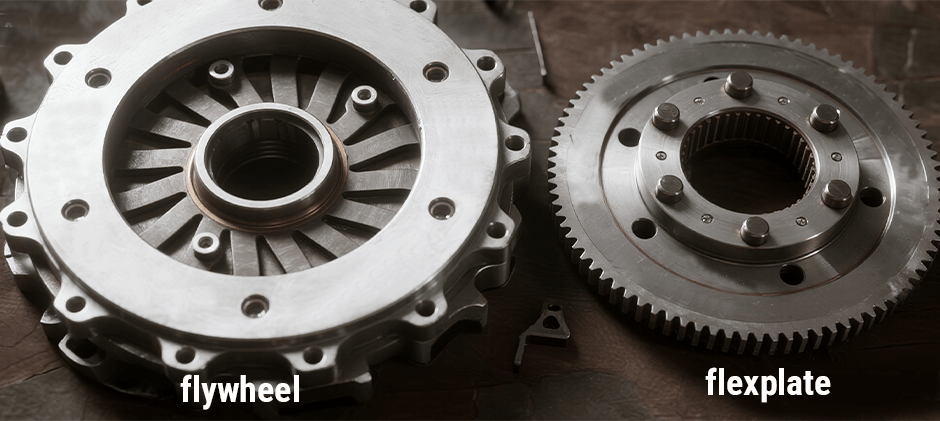

Ever been ordering parts for your engine and gotten stumped when asked, “Do you have a flywheel or a flexplate?” You’re not alone. At FridayParts, we get this question daily from customers who aren’t quite sure what they’re looking at. These two parts do similar jobs but in very different ways, and knowing which one you have is crucial when you’re ordering parts or diagnosing problems. Let’s clear up the confusion once and for all.

Understanding Flywheel and Flexplate: The Basics

Think of flywheels and flexplates as the middlemen between your engine and transmission. They both bolt to the back of your crankshaft and connect to your transmission, but that’s where the similarities end. The main difference? Manual transmissions use flywheels, while automatic transmissions use flexplates.

A flywheel is a heavy metal disc – we’re talking 15 to 50 pounds of solid steel or iron. It’s called a flywheel because it stores rotational energy like a wheel, helping your engine run smoothly between power strokes. When you push in your clutch pedal, you’re disengaging the clutch from the flywheel’s surface.

A flexplate, on the other hand, is much lighter and thinner, usually just a stamped steel disc weighing 5 to 15 pounds. It’s called a flexplate because it can flex slightly without breaking. Instead of providing a friction surface for a clutch, it has teeth around the outside for your starter to engage and mounting points for your torque converter.

“I always tell customers to think of it this way,” says a transmission shop owner we work with. “If you shift your gears, you’ve got a flywheel. If your transmission shifts for you, you’ve got a flexplate.”

Physical Differences: Weight, Design, and Construction

Let’s get into what makes these parts so different when you’re holding them in your hands. The physical differences are dramatic, and once you know what to look for, you’ll never confuse them again.

Flywheel Characteristics:

- Weight: 15-50 pounds (heavy enough to be a workout)

- Thickness: 1-2 inches of solid metal

- Material: Cast iron or steel, sometimes aluminum in performance applications

- Surface: Smooth, machined face for clutch contact

- Design: Solid disc, sometimes with lightning holes in performance versions

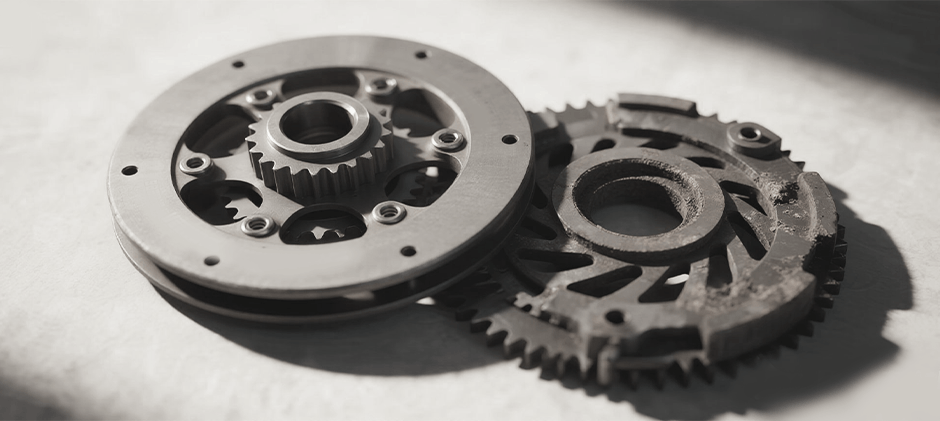

Flexplate Characteristics:

- Weight: 5-15 pounds (you can easily lift with one hand)

- Thickness: Usually 1/8 to 1/4 inch

- Material: Stamped steel

- Surface: No friction surface needed

- Design: Ring of holes for torque converter bolts, teeth around the outside

The weight difference isn’t just random – it serves a purpose. A flywheel’s mass helps smooth out your engine’s power pulses. Every time a cylinder fires, it gives the crankshaft a push. Between those pushes, the flywheel’s momentum keeps things spinning smoothly. Without it, your engine would feel jerky and rough.

A flexplate doesn’t need all that mass because the torque converter in your automatic transmission is filled with fluid that does the smoothing job. That’s why automatics can get away with a light flexplate – the torque converter is doing the heavy lifting (literally).

Functional Roles in Manual vs Automatic Transmissions

Understanding what these parts do helps explain why they’re built so differently. Each is perfectly designed for its specific transmission type.

How a Flywheel Works:

In a manual transmission setup, the flywheel serves three main jobs:

- Energy storage: Keeps the engine spinning smoothly between power strokes

- Clutch surface: Provides a friction surface for the clutch disc

- Starter engagement: Ring gear teeth let the starter turn the engine

When you press the clutch pedal, you’re pushing the clutch disc away from the flywheel. Let the pedal out, and the clutch disc presses against the flywheel, transferring engine power to your transmission. The flywheel’s surface takes serious abuse – all that friction generates heat and wear every time you shift.

How a Flexplate Works:

The flexplate has a simpler job:

- Connection point: Bolts the torque converter to the engine

- Starter engagement: Ring gear for the starter motor

- Flexibility: Absorbs minor misalignment between the engine and transmission

The flexplate doesn’t need a friction surface because there’s no clutch. Instead, it has a circle of holes where the torque converter bolts on. The torque converter uses fluid coupling to transfer power, so the flexplate just needs to hold everything together and let the starter spin the engine.

“The beauty of a flexplate is its simplicity,” notes one experienced mechanic. “No friction surface to wear out, no need for resurfacing. When they fail, it’s usually from fatigue cracks, not wear.”

How to Identify Which One You Have

Sometimes you need to figure out what you’ve got without crawling under your vehicle. Here are foolproof ways to identify whether you’re dealing with a flywheel or flexplate.

The Transmission Test:

This is the easiest method – just look at your gear shifter:

- Manual transmission (you shift gears yourself) = Flywheel

- Automatic transmission (it shifts for you) = Flexplate

Visual Inspection Methods:

If you can see the part (engine out or from underneath):

- Flywheel: Thick, heavy disc with a smooth, machined face

- Flexplate: Thin, light disc with visible torque converter bolt holes

Weight Test:

If you’re holding the part:

- Can you easily lift it with one hand? It’s a flexplate

- Does it feel like a boat anchor? That’s a flywheel

Part Number Clues:

When ordering parts, the descriptions usually make it clear:

- Flywheel part numbers often include clutch-related terms

- Flexplate part numbers mention an automatic transmission or a torque converter

Sound Differences:

A failing flywheel often causes clutch chatter or grinding noises when shifting. A cracked flexplate makes a distinctive knocking or rattling sound, especially at idle. One customer described it perfectly: “It sounded like someone hitting my oil pan with a hammer at idle.”

Common Problems and Symptoms for Flywheel and Flexplate

Both flywheels and flexplates can fail, but they show different symptoms and fail for different reasons. Knowing what to look for can save you from a roadside breakdown.

Flywheel Problems:

1. Hot Spots and Warping

- Caused by riding the clutch or aggressive driving

- Symptoms: Clutch shudder, vibration when engaging the clutch

- Fix: Resurface or replace (usually $200-400 for resurfacing)

2. Worn Friction Surface

- Normal wear from clutch use

- Symptoms: Clutch slipping, difficulty shifting

- Fix: Resurface if enough material is left; otherwise, replace

3. Broken Ring Gear Teeth

- Usually from starter motor issues

- Symptoms: Grinding noise when starting, starter spins, but engine doesn’t start

- Fix: Ring gear replacement or complete flywheel replacement

Flexplate Problems:

1. Fatigue Cracks

- The most common flexplate failure

- Symptoms: Knocking sound at idle, gets worse with engine speed

- Fix: Replacement only (cannot be repaired)

2. Broken Mounting Bolts

- From improper torque or worn bolts

- Symptoms: Severe vibration, rattling noise

- Fix: Replace the flexplate and bolts

3. Warped or Bent

- Often from improper installation

- Symptoms: Vibration throughout the RPM range

- Fix: Replacement required

“In my 30 years of wrenching, I’ve learned that flexplate noises are often misdiagnosed as rod knocks,” shares a veteran mechanic. “Always check the flexplate first – it’s a lot cheaper than rebuilding an engine!”

Replacement Costs and Considerations

When it comes time to replace your flywheel or flexplate, the costs can vary widely depending on your vehicle and whether you’re doing the work yourself or paying for labor. Let’s break down what you’re looking at.

Flywheel Replacement Costs:

- Part cost: $50-500 (depending on vehicle and type)

- Labor: $400-800 (4-8 hours typically)

- Total: $450-1,300

The wide range in flywheel costs comes from different types:

- Standard OEM replacement: $50-200

- Heavy-duty upgraded: $200-400

- Lightweight performance: $300-500

- Dual-mass flywheels: $300-800 (common in European vehicles)

Flexplate Replacement Costs:

- Part cost: $50-200 (generally cheaper than flywheels)

- Labor: $300-600 (3-6 hours typically)

- Total: $350-800

Money-Saving Tips:

- Buy quality parts the first time – Cheap flywheels and flexplates often fail prematurely

- Replace related parts – If you’re pulling the transmission, replace the rear main seal

- Check your warranty – Some flexplate failures are covered under powertrain warranties

- Consider resurfacing – Flywheels can often be resurfaced for $50-100 instead of being replaced

At FridayParts, we stock both OEM-quality replacements and performance upgrades. We’ve learned that saving 50onacheapflexplateoftencostsyou50 on a cheap flexplate often costs you 50onacheapflexplateoftencostsyou500 in labor when it fails six months later.

Choosing Quality Replacement Parts for Flywheel and Flexplate

Not all flywheels and flexplates are created equal. The market is flooded with cheap imports that might look right but won’t last. Here’s what to look for when shopping for replacements.

Quality Indicators for Flywheel:

- Proper weight: Should match OEM specifications

- Balance marks: Quality flywheels are balanced at the factory

- Smooth machining: No rough spots or visible defects

- Heat treatment: Proper hardening prevents warping

- Brand reputation: Stick with known manufacturers

Quality Indicators for Flexplate:

- SFI certification: For high-performance applications

- Proper steel thickness: Cheap ones are often too thin

- Clean stamping: No rough edges or stress points

- Correct bolt pattern: Double-check torque converter spacing

- OEM specifications: Should match the original exactly

Red Flags to Avoid:

- Prices that seem too good to be true (they usually are)

- No brand markings or identification

- Lightweight flywheels for daily drivers (they increase NVH)

- Universal fit claims (these parts are vehicle-specific)

- Missing balance weights or marks

“I’ve installed hundreds of flywheels and flexplates,” says a transmission shop owner. “The difference between quality and junk is obvious when you hold them. Quality parts have heft, clean machining, and proper markings. Cheap ones feel like they’re made from recycled cookie sheets.”

Making the Right Choice for Your Vehicle

Whether you’re dealing with a flywheel or flexplate, the key to avoiding problems is understanding what you have and maintaining it properly. These parts might be hidden between your engine and transmission, but they play a crucial role in keeping your vehicle moving.

At FridayParts, we’ve been helping customers identify and source the right flywheels and flexplates for over 16 years. We know it can be confusing when you’re staring at a parts catalog trying to figure out what you need. That’s why we’re here to help – our team knows the difference and can guide you to the right part the first time.

Remember, whether you’re shifting your gears with a flywheel or letting an automatic do the work with a flexplate, quality parts and proper installation are key. Don’t let a 100partcostyou100 part cost you 100-part cost you 1,000 in labor because you tried to save a few bucks on an inferior replacement.

Keep your flywheel or flexplate in good shape, and it’ll keep you rolling down the road. Because at the end of the day, we want you enjoying that Friday night relaxation, not dealing with transmission problems on Monday morning.

Need a flywheel or flexplate? FridayParts stocks thousands of OEM-quality replacements for all major equipment brands. With warehouses worldwide and over 70,000 parts in inventory, we’ll get you the right part fast. Visit FridayParts.com or call our experts – we’ll make sure you get exactly what you need to fix it once and fix it right.