If you’ve ever asked, “What is an intercooler?”, you’ve come to the right place. An intercooler is a heat exchange device to cool compressed air from a turbocharger or supercharger before it enters the engine. Cooling this air helps improve engine performance, prevent damage from overheating, and increase efficiency. This guide covers everything you need to know about intercoolers, including how they work, their different types, maintenance tips, applications, and more.

Key Takeaways

- An intercooler is a device that cools down compressed air before it enters the engine.

- It’s a vital part of high-output, boosted engines.

- The two principal types of intercooler are air to air intercooler and air to water intercooler.

How Does An Intercooler Work

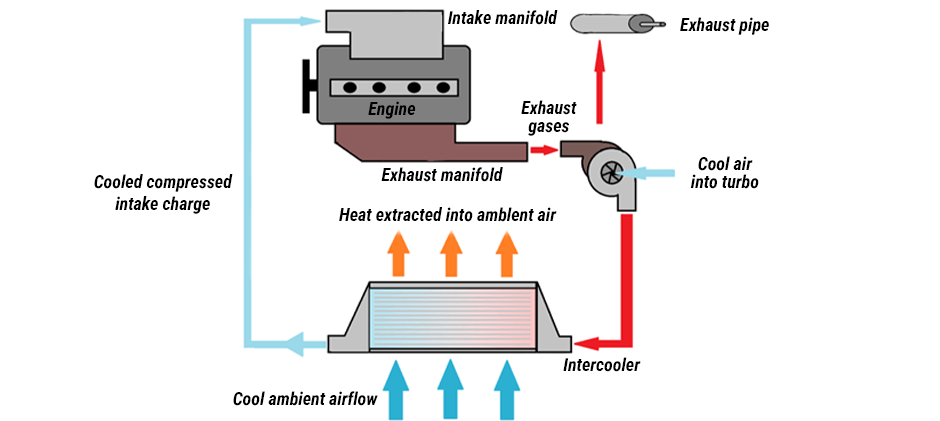

An intercooler reduces the temperature of intake air after it’s been compressed by a turbocharger or supercharger.

To understand how an intercooler works, you first need to know what happens during forced induction. When a turbo or supercharger compresses air to force more into the engine’s cylinders, the air heats up significantly, sometimes exceeding 200°C (392°F). This is a fundamental principle of physics: compressed air becomes hotter.

Hot air is less dense, meaning it contains fewer oxygen molecules per unit volume. Since oxygen is essential for combustion, hot air leads to less efficient fuel burning and reduced power. This is where the intercooler steps in.

Hot air flows through the intercooler’s tubes and cooling fins, which dissipate heat to the surrounding atmosphere. As the air cools, it becomes denser and richer in oxygen. This air then enters the engine, enabling more fuel to be burned and producing a more powerful, efficient combustion cycle.

What is the Purpose of An Intercooler

An intercooler is essential for any modern engine that uses forced induction for several key reasons:

- Increased Horsepower and Torque: Cooler, denser air allows the engine to burn more fuel efficiently, directly translating to a significant increase in power and torque.

- Improved Engine Reliability: High intake air temperatures can lead to a dangerous condition called “engine knock” or detonation, which can cause severe engine damage. By keeping temperatures down, an intercooler protects the engine and reduces thermal stress on critical components like pistons and valves, extending the engine’s life.

- Better Fuel Efficiency: A more complete and efficient combustion process means the engine can produce more power from the same amount of fuel, which can lead to improved fuel economy.

- Consistent Performance: An intercooler helps maintain a stable intake air temperature, ensuring the engine performs reliably and consistently, even under heavy loads or in varying weather conditions.

Applications

- Performance and passenger cars.

- Commercial and light-duty trucks.

- Heavy-duty diesel engines are used in construction and agricultural machinery.

- Marine engines.

- Stationary industrial engines and air compressors.

Types of Intercooler

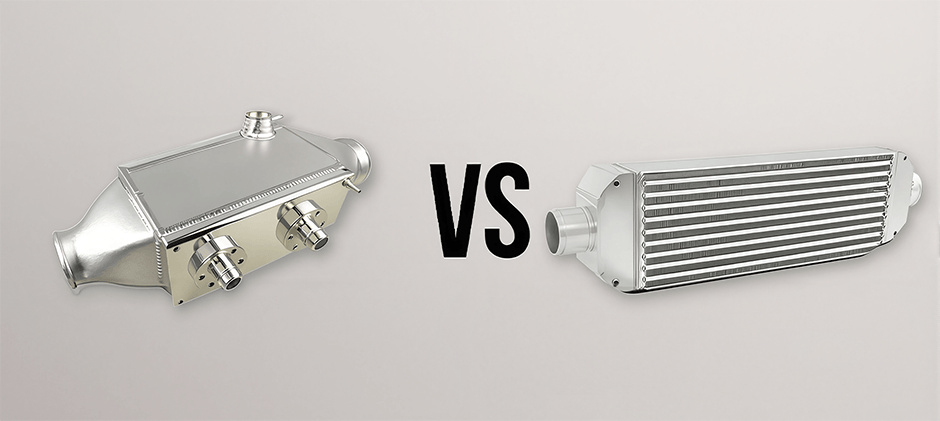

Intercoolers have two main types: air-to-air and air-to-water, based on how they transfer heat.

1. Air to Air Intercooler

This is the most common type of intercooler. It works by passing the hot charge air through a core of tubes and fins, while outside air from the moving machinery flows over the fins to carry the heat away. They are often mounted at the front of the off-road machinery to get maximum airflow, but can also be found on top of the engine.

Advantages:

- Simplicity: With no moving parts or complex plumbing, they are simple and reliable.

- Lower Cost: Their straightforward design makes them less expensive to manufacture and purchase.

- Lightweight: They add less weight to the machinery compared to air-to-water systems.

- Low Maintenance: They require very little maintenance due to their simple construction.

Disadvantages:

- Placement Dependent: Their efficiency is highly dependent on the machinery speed and placement. Front-mount intercoolers are very effective but can require long intake piping, which may slightly increase turbo lag.

- Heat Soak: Top-mounted units can suffer from “heat soak,” where heat from the engine reduces their cooling efficiency, especially at low speeds or when stationary.

Placement

The best placement for an air-to-air intercooler is at the front of the machinery, which is the most effective position. If the layout cannot use the “front-mount” placement, the intercooler can be installed on top of the engine or even on its side. These positions typically require additional air ducts or scoops to direct air into the intercooler. However, these methods are less practical because the airflow is less efficient. As a result, the intercooler may experience heat soak from the engine when external airflow decreases.

2. Air to Water Intercooler

An air-to-water intercooler uses liquid coolant to cool the charged air. The system consists of a compact intercooler unit, a separate radiator to cool the liquid, a pump, and connecting lines. The charge air heats the coolant, which is then pumped to the radiator to release the heat into the atmosphere.

Advantages:

- Superior Cooling Efficiency: Water is much more effective at transferring heat than air, providing more stable and consistent intake temperatures.

- Flexible Placement: Because the intercooler unit itself doesn’t need direct airflow, it can be placed anywhere in the engine bay, allowing for much shorter intake piping and reduced turbo lag.

- Consistent Performance: They are less affected by vehicle speed and can maintain low temperatures even when the vehicle is stationary, thanks to the pump and dedicated cooling fan.

Disadvantages:

- Complexity and Cost: The system is more complex, involving a pump, radiator, and coolant lines, which makes it heavier and more expensive.

- More Potential Failure Points: The added components introduce more potential points for leaks or failure.

Placement

The air-to-water can be placed anywhere in the engine bay as long as the radiator is in a position with good airflow or a Thermo fan connected to it.

| Types | Air-to-Air | Air-to-Water |

|---|---|---|

| Primary Strength | Simple, reliable, and low-cost. | Superior and highly consistent cooling. |

| Primary Weakness | Cooling efficiency depends on vehicle speed. | Complex, expensive, and heavier. |

| Placement | Limited; requires direct airflow. | Highly flexible; allows for short piping. |

| Performance | Longer piping can increase turbo lag. | Shorter piping improves throttle response. |

Another common point of confusion is the difference between a radiator and an intercooler. For a detailed breakdown, you can read our full guide: Intercooler vs Radiator: What’s the Difference?

How Intercooler Size Affects Performance?

An intercooler’s size affects the cooling efficiency, pressure drop, and response time. While a larger intercooler has a greater surface area and can cool air more effectively, it can also lead to negative effects. A very large core can cause a serious drop in boost pressure as air travels through it, and its larger internal volume can increase turbo lag, slowing the engine’s throttle response. It’s wise to choose an intercooler that is large enough for the engine’s boost level and intended use without being too large to hurt performance.

The Future of Intercooling Technology

Today, intercoolers are stronger and work better than ever. We are seeing new technologies like improved core designs, intercoolers that are into the engine’s intake, and even systems that spray a fine mist of water to remove heat instantly.

In the future, new materials and better techniques will improve intercoolers even more. They will become lighter and smaller, and the technology will change to work with new kinds of equipment.

Bad Intercooler Symptoms

These are the noticeable signs that may indicate an issue with the intercooler.

Issues Caused by Leaks

A leak in the intercooler core, intercooler piping, or a cracked intercooler hose means compressed air is escaping before it reaches the engine. This leads to several problems:

- Sluggish Acceleration and Power Loss: A noticeable delay in the equipment’s response is a classic sign of a boost leak. Because not enough air is reaching the engine, the air-fuel ratio is disrupted (running “rich” with too much fuel), leading to inefficient combustion and a drop in power.

- Black Smoke from Exhaust: The rich air-fuel mixture results in unburnt fuel being ejected into the hot exhaust system, where it combusts and creates visible black smoke.

- Extra Turbo Whine or Whistling Sound: You may hear an unusual whining or whistling sound as the turbocharger works harder (spins faster) to compensate for the escaping air pressure.

- Activation of “Limp Mode”: In response to a major leak, the equipment’s computer may restrict engine power and RPM to prevent damage. This protective state makes driving difficult and is a clear sign of a serious issue.

Issues Caused by Clogs

A clog prevents the intercooler from cooling efficiently. This can be an external clog (dirt, mud, debris on the fins) or an internal clog (oil buildup from the turbo).

- Engine Overheating and Knocking: When the intercooler is clogged, its ability to cool the compressed air is drastically reduced. This leads to hotter, less dense air entering the engine. This not only reduces power but also significantly increases the risk of engine overheating and “knocking,” which can cause severe internal damage.

- Reduced Performance and Fuel Economy: Hotter air is less efficient for combustion. The engine control unit may try to compensate, but the overall result is a noticeable drop in the equipment’s power and an increase in fuel consumption.

Intercooler Maintenance Tips for Off-Road Equipment

It’s wise to inspect and potentially clean the intercooler at least once a year, every 250 hours, or during routine filter changes, depending on your maintenance schedule. If you notice performance issues like power loss or excessive smoke, or if you frequently operate in dusty or dirty environments, you need to clean it more often.

To extend your intercooler’s lifespan, you’d follow these tips.

- Regular Cleaning: You need to clean the exterior of the intercooler with a brush or compressed air to remove any contamination.

- Inspect the Turbocharger: Turbochargers can leak small amounts of oil into the intercooler over time. This oil can reduce the intercooler’s effectiveness, and you need to clean it professionally or even replace the turbocharger if it’s a serious issue.

- Performance Checks: If you experience a noticeable drop in engine power, increased fuel consumption, or excessive exhaust smoke, it could indicate a problem with the intercooler. So, regularly checking the intercooler is necessary.

- Professional Inspection: For optimal performance and to discover potential problems early, it’s wise to turn to a mechanic at least once a year or when you notice any performance issues.

Conclusion

By knowing what an intercooler is, its function, the different types available, the failing signs and effects of an intercooler, and the maintenance tips, you can better understand its importance in modern machinery. Whether you are maintaining a fleet of heavy equipment or improving a performance vehicle, ensuring your intercooler is in top condition is vital. At FridayParts.com, you’ll find a high-quality replacement intercooler or a full intercooler kit designed to restore your engine’s performance and reliability. Explore our selection today to keep your machinery running at its best.