The final drive (also known as a travel or track motor) is the powerhouse that moves your excavator. It’s the critical component responsible for turning hydraulic energy into the high-torque force needed to move the tracks on any terrain. This guide breaks down the excavator final drive diagram key components and how a final drive works.

What is an Excavator Final Drive?

An excavator final drive, also known as a travel motor or track motor, is a compact and powerful gearbox assembly that connects the excavator’s hydraulic system to its tracks. Its single, vital job is to convert hydraulic power from the main pump into the high-torque, low-speed rotation needed to move the machine. Without a functioning final drive, the tracks will fail to rotate, and your excavator will be completely unable to move.

How Does the Final Drive Work in an Excavator?

The operation follows a clear sequence:

- Hydraulic Fluid Input: The excavator’s main pump sends high-pressure hydraulic fluid to the final drive’s hydraulic motor.

- Energy Conversion: The hydraulic motor converts this fluid pressure into high-speed, low-torque rotational motion.

- Torque Multiplication: This rotation is then fed into a planetary gear reduction system. The gears work to drastically slow the rotation down while multiplying the torque.

- Power Output: The resulting low-speed, high-torque rotation is sent to the main output shaft, which turns the track sprocket and moves the excavator.

This conversion is what gives an excavator the brute force to climb steep grades, navigate rough terrain, and push heavy loads.

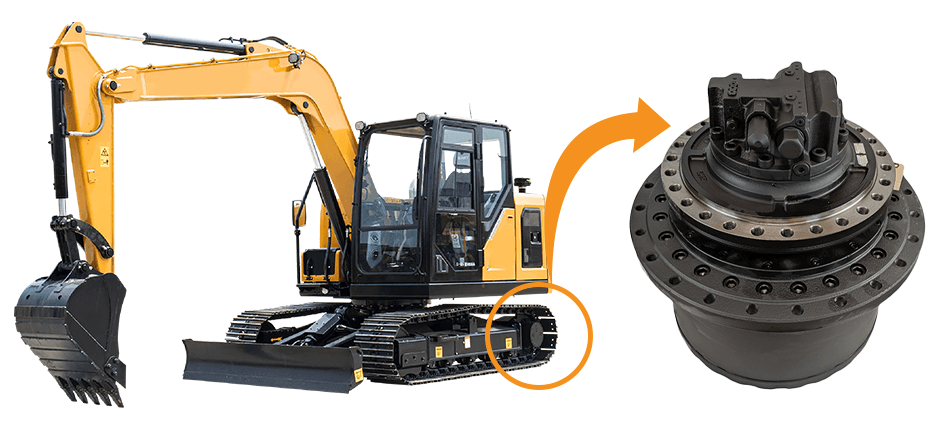

Where on a Machine is the Final Drive Located?

You will find a tracked excavator final drive diagram mounted to the undercarriage frame at the center of each track. It is the component that the drive sprocket is bolted onto. Its location is strategic, allowing it to directly transfer power to the tracks for maximum efficiency and control. While designs vary between machines, its function as the final link in the power transmission chain remains the same.

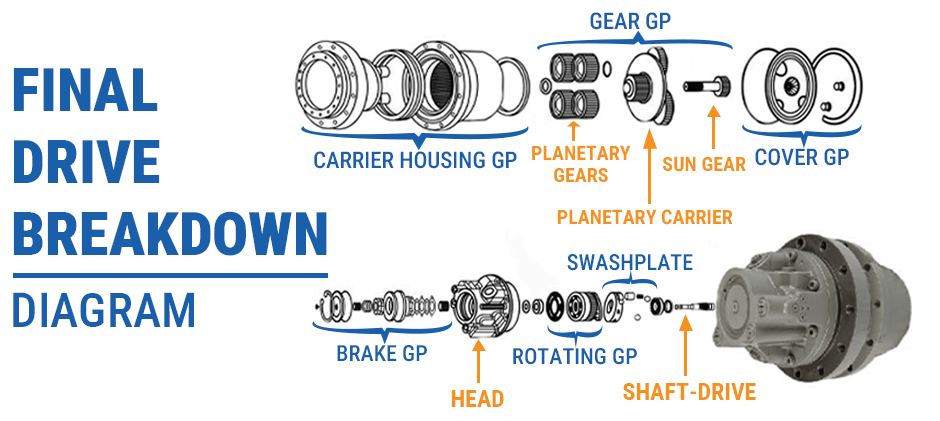

Key Components of the Excavator Final Drive Diagram

To truly understand an excavator’s final drive parts, we need to look inside its casing. While it appears as a single unit, it is a complex assembly of parts working in perfect sync. The diagram below illustrates how these core components fit together.

Hydraulic Motor

The hydraulic motor is the heart of the final drive. It takes pressurized hydraulic fluid from the excavator’s main pump and transforms it into mechanical energy. By efficiently converting hydraulic energy, it enables the excavator to perform tasks such as digging, lifting, and traveling over uneven terrain. Think of it as the engine of the travel system. Its efficiency directly impacts the machine’s travel speed and pushing power. A strong, responsive hydraulic motor ensures the machine can move precisely as the operator intends.

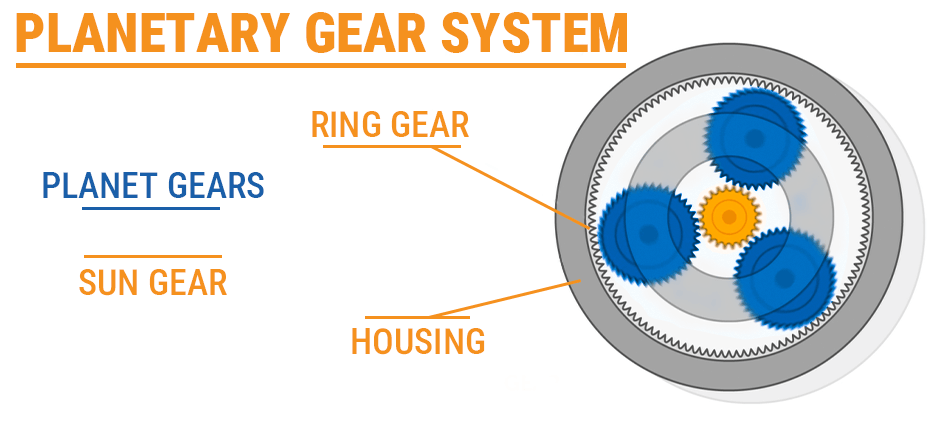

Planetary Gears

This is where the key to torque multiplication happens. The planetary gear system is what turns the fast, weak spin of the hydraulic motor into the slow, powerful rotation needed to move tons of steel. It consists of three main gear types:

- Sun Gear: The central gear that receives the initial rotation from the hydraulic motor.

- Planet Gears: A set of smaller gears that orbit the sun gear.

- Ring Gear: The outer, stationary gear with internal teeth that the planet gears mesh with.

As the sun gear spins, it turns the planet gears. Because the planet gears are also engaged with the stationary ring gear, they are forced to “walk” around the inside of the ring gear, carrying their mounting bracket (the carrier) with them at a much slower speed. This gear reduction is the secret to immense torque. By trading speed for power, the planetary gearbox gives the excavator the force needed for heavy-duty work on challenging off-road sites.

Main Shaft & Output Shaft

Often called the final drive shaft, this is the robust component that delivers the final, high-torque power from the planetary gear system to the track sprocket. This shaft is a solid piece of forged, high-strength steel because it must withstand the entire rotational force generated by the drive without twisting or breaking. It acts as the final link in the power transmission chain. The integrity of the output shaft is non-negotiable; If it fails, the connection between the motor and the track is completely lost, so the track can’t move.

Bearings and Seals

Hidden from view but absolutely essential, bearings and seals ensure the final drive operates smoothly and lasts a long time.

- Bearings support the rotating shafts and gears, allowing them to spin freely under extreme loads while minimizing friction. Without them, the metal-on-metal contact would quickly destroy the internal components.

- Seals have two jobs: keeping the vital gear oil inside the housing and keeping contaminants like dirt, water, and grit out. If lubricant leaks out or abrasive grit gets in, it will rapidly destroy the bearings and gears, turning a minor repair into a complete system replacement.

Casing

The casing is the rugged outer shell that encloses and protects all the critical internal components of the final drive. Made from heavy-duty cast iron or steel, it serves as a protective shield against the harsh off-road work environment, defending the delicate gears and motor from external impacts, rocks, and debris.

Beyond just protection, the housing provides the structural framework that holds all the parts in precise alignment. It also acts as a reservoir, containing the gear oil that lubricates the system. A crack or breach in the casing can lead to a loss of lubricant and expose the internals to contamination, leading to the same destructive outcome as a failed seal. Regular inspection of the casing for cracks or damage is a simple but crucial step in maintaining the health of your final drive.

When to Replace Excavator Final Drive Parts?

Recognizing the warning signs can save you from a sudden on-site failure and more expensive repairs. It’s time to inspect your final drive parts if you notice:

- Grinding, Popping, or Clicking Noises: This often points to damaged gears or worn-out bearings inside the gearbox.

- Leaking Fluid: If you see gear oil or hydraulic fluid dripping from the drive, it’s a clear sign of a failed seal. This is a critical issue that needs immediate attention to prevent internal damage.

- Loss of Power or Speed: If one track is weaker or slower than the other, it could indicate wear in the hydraulic motor or a problem within the gearbox.

- Excessive Vibration: Unusual vibration during travel can signal that bearings are failing or gears are no longer meshing correctly.

Choose the Right Replacement Parts

The final drive is a powerhouse of engineering in an excavator. By learning its key components, from the hydraulic motor to the planetary gears, and finding the signs of wear, you can perform timely maintenance. When a component fails, the quality of the replacement part decides the longevity of the fixture. FridayParts offers reliable OEM-quality parts at lower prices. Our extensive inventory covers nearly all popular heavy equipment brands. Shop at our one-stop shop, get back to work quickly and with confidence.