When off‑road machinery refuses to start, the first suspect is often the starter motor. It’s the small but powerful electric component responsible for turning heavy diesel or gasoline engines on until they ignite. Without it, even the most advanced earthmover or tractor won’t run at all. Knowing what a starter motor is, how it works, and what causes failure helps operators prevent downtime and save on expensive repairs.

What Is a Starter Motor?

A starter motor is an electric device that takes the electrical energy stored inside the battery and transforms it into a kind of rotational force so that the engine can be persuaded to begin its movement. It functions as the intermediary that connects the stored power with the mechanical activity. When one turns the ignition key or presses the starting button, the starter shall engage itself for only several seconds — a duration merely sufficient for the engine to commence its own combustion and maintain operation thereafter.

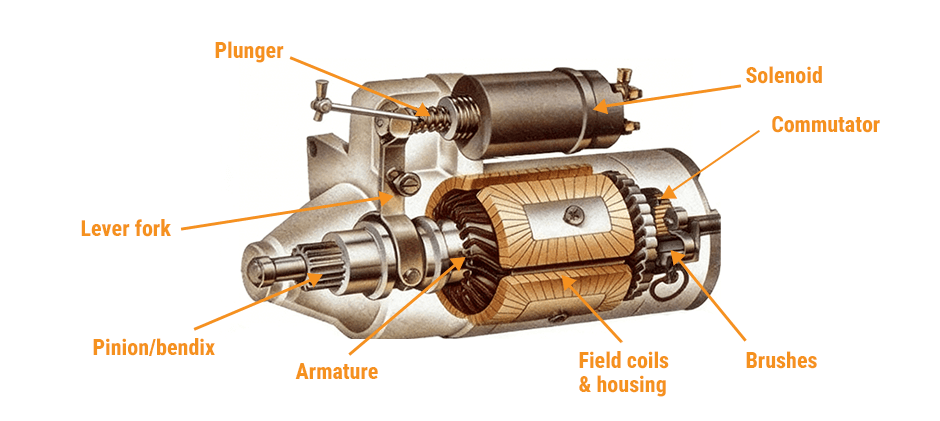

This critical part contains three main pieces:

- A solenoid, which establishes a duration with the battery and urges a small gear toward the engine.

- A pinion gear, which engages the flywheel of the engine.

- The motor body, which produces a torque of considerable magnitude by means of winding coils and magnetic force.

When acting in unison, these components permit the machine to surmount the compression of the cylinders and the internal friction that appear during cold starting. Most off-road machines employ electrical systems of 12 volts or 24 volts. Engines of smaller scale, such as those upon compact tractors, commonly depend upon 12-volt units, whereas excavators or loaders of larger structure adopt 24-volt systems in order to withstand their more substantial compression demands.

How Does a Starter Motor Work?

The process of engine ignition begins the instant current reaches the starter solenoid:

- The operator turns the ignition key or presses the start switch.

- The solenoid receives a low‑voltage signal and closes a high‑current connection from the battery.

- A metal plunger pushes the pinion gear forward into the flywheel’s teeth.

- The motor spins, rotating the engine’s crankshaft until combustion takes over.

- As soon as the engine fires, the solenoid retracts the gear to prevent damage.

This operation lasts only a few seconds, but during that time, the starter motor draws more power than any other electrical component in the system. That’s why any weakness in wiring, battery health, or grounding quickly shows up as slow cranking or clicking sounds.

Correct voltage selection is critical. 12V starter motors serve small and medium equipment such as utility tractors, compact loaders, and skid steers. 24V starter motors suit larger machinery that operates in demanding environments where higher torque is required. Using the wrong voltage can burn internal components or damage the electrical harness.

If you’re uncertain which model fits your engine, FridayParts provides a complete list of heavy‑duty and compact starter motor assemblies with verified engine compatibility—such as units for Kubota D902, Yanmar 3TNV88, Mitsubishi, Deutz, and John Deere engines.

What Causes Starter Motor Failure?

Starter motors are built for durability, but heavy‑duty use, dirt, heat, and vibration eventually wear them down. The most common failure sources include:

| Failure Cause | Description | Symptoms |

|---|---|---|

| Worn Bendix drive | The pinion gear fails to mesh fully with the flywheel | Whirring or grinding sound |

| Faulty solenoid | Contacts burned or stuck | Single “click” when the key turns |

| Corroded terminals | Weak current flow or voltage drop | Slow or weak crank |

| Worn brushes or bearings | Mechanical drag or poor contact | Irregular starting, high current draw |

| Overheating or moisture | Internal damage to windings or insulation | Burning smell or smoke |

In off‑road machines, exposure to dust, mud, and hydraulic oil accelerates failure. If your equipment struggles to crank even with a good battery, inspection or replacement is necessary.

Maintenance and Early Warning Signs

Avoiding starter failure starts with routine checks. During pre‑operation inspections, watch for:

- Unusual clicking or grinding during start‑up.

- Heat or smell near the starter casing.

- Sluggish cranking despite a fully charged battery.

- Intermittent starting that only works after tapping the housing.

Simple maintenance tasks—cleaning battery terminals, tightening ground straps, ensuring insulation remains intact—can extend service life dramatically. Starters draw hundreds of amps, so even small resistance in connectors can cripple performance.

A preventive mindset also pays off when machines sit idle. Disconnecting the battery during seasonal storage stops parasitic current that could weaken the battery and strain the motor at the next startup.

Replacing and Choosing the Right Starter Motor

Once the starter shows consistent failure signs, replacement is more efficient than repair. The key to selecting the right one lies in matching three parameters:

- Voltage – 12V or 24V, depending on the system.

- Tooth count (T) – The number of teeth on the pinion must match the flywheel.

- Engine model or OEM number – Printed directly on the old unit or in equipment manuals.

Aftermarket suppliers like FridayParts make this process simple with clearly labeled models and specifications. Their vast collection of starter motors—from 12V 9T Starter Motor 19269‑63013 for Kubota D902 to 24V heavy‑truck assemblies—offers precision fit and long‑life seals suitable for off‑road conditions. Each unit undergoes torque and performance testing before shipment, ensuring the same reliability you’d expect from OEM components but at a more accessible price.

For operators working in remote areas, keeping a spare starter in the service truck can save days of downtime during critical seasons like construction peak or harvest.

Can a Starter Motor Drain the Battery?

A working starter consumes power for only a few seconds. It does not continuously drain the battery. However, internal short circuits, stuck solenoids, or repeated failed start attempts can quickly deplete the charge.

Before replacing the motor, check:

- Battery charge level (should stay above 12.6 V).

- Integrity of all positive and ground cables.

- Relay and solenoid condition.

If power checks out but the motor doesn’t turn, the internal contacts or armature likely need replacement.

Conclusion

In the world of off‑road machinery, reliability begins with a dependable starter motor. It’s the unsung component that transforms stored electrical power into the first burst of motion. Understanding how it operates and identifying early symptoms lets us prevent equipment downtime and maintain steady productivity.

When replacement becomes necessary, choosing a tested, correctly matched aftermarket unit ensures dependable starts without inflating costs. Explore the full selection of high‑quality, durable starter motors from FridayParts—built for loaders, tractors, excavators, and other heavy equipment—to keep every job starting smoothly.