The PTO (Power Take-off) sends the tractor’s power straight to all kinds of farm implements, making a lot of work easier and more efficient. You usually have to engage it by hand, and it relies a lot on manual operation. So how to engage PTO on a Kubota tractor? Today, we’ll show you the right way to do it, plus some common issues you might run into while doing it.

What Is the PTO System?

The PTO (Power Take-Off) isn’t all that complicated. It just takes power from the tractor’s engine and sends it to the farm implements hooked up to the front or back—letting those tools without their own engines spin right up. Think of it as a universal power port on your tractor: mowers, tillers, post-hole diggers, wood chippers, they all run off it.

The PTO is separate from the tractor’s drive system for moving. That means you can drive slow, drive fast, or even stop the tractor entirely, and the implement will still keep spinning at the same speed. That’s what makes the PTO so flexible to use. But you have to follow the steps to engage, and you won’t damage your equipment.

How to Engage PTO on Kubota Tractor?

Engaging the PTO needs to be done slow and steady—never rush it. Kubota models have slight differences in where the controls are, but the basic steps are all the same.

Prep and Safety First

Park your tractor on flat ground and set the parking brake tight. Make sure no one’s near the PTO shaft or the implement. And double-check that the implement matches your tractor’s PTO speed (it’s usually 540 RPM or 1000 RPM). Using a mismatched one will damage both the tractor and the tool for sure.

Find the PTO Controls

On most Kubotas, the PTO lever is easy to reach, right by the operator’s seat—usually it’s yellow, so it stands out. There’s also a PTO light on the dash that lights up when it’s on. Just get to know where the ON and OFF positions are.

Engage the PTO Step by Step

- Start the engine: Fire up your Kubota and let it warm up a few minutes. This gets the hydraulic fluid to the right temp, so engagement’s smoother.

- Lower the RPM: Turn the throttle down to low idle. Engaging the PTO at high RPM slams a huge load on the whole driveline.

- Press the clutch all the way: Push the main clutch pedal to the floor. This cuts the engine power to the transmission and PTO, so the parts connect without grinding.

- Flip the PTO lever: Move it from OFF to ON smooth and firm—don’t jam it. You’ll feel it lock in solid.

- Let the clutch out slow: Ease up on the clutch pedal. You’ll hear the implement start spinning, and feel the engine pick up the load.

- Crank up to working RPM: Once the implement’s spinning freely, slowly push the throttle up until the tachometer hits the right speed for your tool (like 540 RPM).

Check Everything, then Get toWork

Glance at the implement to make sure it’s running right, and listen for any weird noises. Check the dash—your PTO light should be on. If all looks and sounds good, you’re ready to go. To turn the PTO off, just do the steps in reverse: drop the RPM to idle, press the clutch, flip the lever to OFF, then let the clutch out slow.

Tips to Limit Shock and Wear

How you engage the PTO directly affects how long your tractor’s clutch, gearbox and the implement last. Stick to the right habits, and you’ll save a ton on repair costs. The biggest mistake operators make is turning on the PTO when the engine’s revving at medium or high speed. This slams a hard jolt through the whole system—just like dumping the clutch in a manual car when it’s at 4,000 RPM. This shock is extra tough on heavy, high-inertia implements, like big rotary cutters (bush hogs), where the heavy blades spin like a flywheel. Here’s how to minimize wear and tear:

- Always engage and disengage at idle – We can’t say this enough. Firing up the PTO at low idle lets the PTO clutch connect slowly, soaking up the torque without a harsh jolt.

- Always use the main clutch – Pressing the clutch pedal isn’t an option. It’s what lets the engine and PTO driveline connect smoothly. Skip this step, and the gears and clutch plates will grind—killing their lifespan fast.

- Pause before disengaging heavy implements – For big mowers and the like, the blades keep spinning long after you cut the power. Turning off the PTO at idle eases the strain on the PTO shaft’s internal brake, the part that stops the shaft from spinning.

- Get an overrunning clutch if you can – If you use high-inertia implements (mowers, balers), an overrunning clutch is a smart buy. It attaches to the PTO shaft and works like a ratchet: it lets the implement spin down on its own, so it doesn’t try to reverse-drive the tractor’s transmission when you slow down or turn off the PTO.

Troubleshooting Common PTO Issues

Below are some common problems you might encounter when engaging the PTO, along with their solutions.

What if the gear shift lever is stuck?

If your PTO lever won’t move, don’t force it. Check for anything blocking the lever or the linkage—like a random tool, mud, or dirt. That stuff jams the mechanism super easy. If there’s no obstruction, check the whole linkage from the lever all the way down to the transmission case. Look for bent rods or rusted, stuck pivot points. Spraying good penetrating oil on all the pivot points will usually free it up. And one last thing: on some Kubota models, faulty safety interlocks (like the seat sensor) can stop the PTO from engaging. Make sure all the safety features are working right before you try moving the lever again.

Why is the PTO shaft turning when the PTO is not engaged?

This dangerous issue’s usually called PTO creep or hydraulic drag. You’ll see the shaft spin slow at idle, even when the PTO lever’s in the OFF position. It might not have enough power to run an implement all the way, but this is a huge safety risk. This problem almost always comes down to one of three things:

- Worn PTO brake: The internal brake that’s supposed to keep the shaft still is worn out.

- Leaking clutch pack: On hydraulic PTO systems, the inner seals in the clutch pack can leak. That lets just enough pressure build up to engage the clutch a little bit.

- Misadjusted control valve: This is the most common one. The PTO control valve’s a little off, so it can’t fully cut off the hydraulic fluid flow to the clutch.

A tech can do a simple pressure test on the control valve to figure out the exact problem fast. Don’t use the tractor with this issue. It could hurt you, and it’ll damage the PTO brake and clutch parts even more.

Why does the PTO make noise when engaged?

New or unusual noises are your machine’s way of telling you something is wrong. If you hear grinding, whining, or heavy vibration when the PTO is engaged, shut it down and investigate.

- Grinding: Often indicates worn gear teeth or a failing bearing inside the PTO gearbox. It can also happen if you are not fully depressing the clutch during engagement.

- Whining: A high-pitched whine that changes with engine speed usually points to a hydraulic issue, such as low fluid or a failing hydraulic pump.

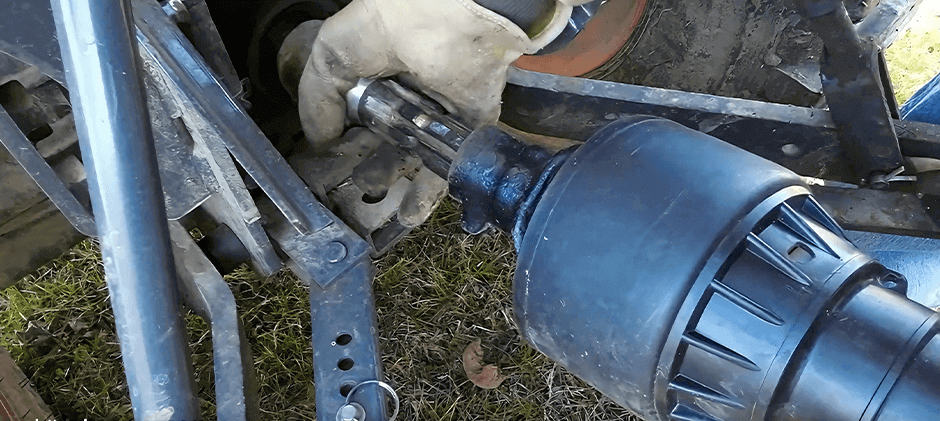

- Vibration: This is frequently caused by the driveline connecting the tractor to the implement. Check the universal joints (U-joints) on the shaft for any play or roughness; they are common wear items. Also, ensure the implement is connected squarely to the tractor, as misalignment will cause severe vibration.

Why does my Kubota PTO disengage on its own?

A PTO that cuts out unexpectedly is a big safety issue. The most common reason is a faulty seat safety switch. Tractors are for shut off the PTO automatically if the operator gets off the seat. If this switch or its wiring is broken, it’ll send a wrong signal and shut the system down. You can test this easily by moving around a bit in the seat—if the PTO cuts out, that’s almost certainly the problem. Other causes includea worn mechanical linkage (it lets the lever vibrate out of the ON position) or, in worse cases, a drop in internal hydraulic pressure that makes the clutch disengage on its own.

In Conclusion

Engaging the PTO on a Kubota tractor needs to be smooth and controlled. Even with good maintenance, the PTO can still have problems for all kinds of reasons—like worn parts, electrical issues or misalignment. You can find all types of Kubota parts at FridayParts. Check things regularly and fix problems as soon as they pop up, to keep your Kubota tractor and PTO system running right.