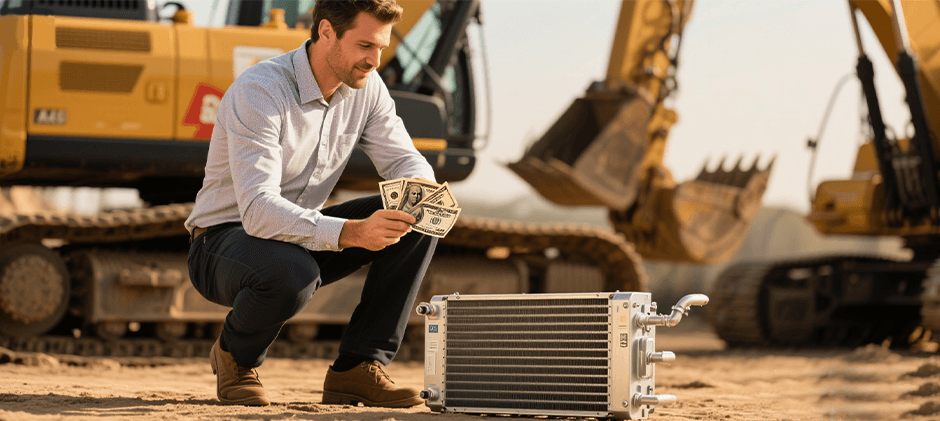

If your heavy equipment cab suddenly starts blowing out hot, humid air and the condition persists, it’s time to consider replacing your AC evaporator. Replacing an AC evaporator isn’t cheap, and prices vary significantly depending on labor costs, parts costs, and region. We’ve researched market prices and compiled a detailed analysis of evaporator replacement costs for your reference.

Key Takeaways: Estimated Replacement Cost

- Total Estimated Cost: $800 to $1,200+

- Aftermarket Parts: $80 – $450+

- OEM Parts: $270 – $600+

- Labor: $420 – $600+ (estimated 6-10 hours of work)

Note: These prices are estimates for heavy-duty equipment, and they may have a significant difference according to the brand and model of your machine, your location, and the specific repair shop.

What are the Symptoms of a Bad AC Evaporator?

The AC evaporator, or evaporator core, is essentially a small radiator inside your dashboard that gets ice-cold. It allows the blower motor to push cool air into the cab. When it fails, the symptoms are usually quite noticeable.

- Warm or Weak Airflow: This is the most common symptom. The evaporator, which is leaking or clogging, cannot effectively absorb the heat from the cabin air. Even if you can hear the compressor clutch engaging and the blower motor operating, the air blowing from the vent is at best only warm.

- A Sweet, Chemical Smell: Inside the evaporator, there is the refrigerant, and inside the refrigerant, there is mixed a special lubricating oil is mixed. If the evaporator core is leaking, then maybe you will be smelling inside the cabin a sweet and chemical odor. This means the refrigerant is leaking.

- Musty or Moldy Odor: The evaporator is naturally collecting the condensation water. If the drain pipe is blocking, this water will breed mildew, and every time you are opening the air conditioner or the fan, it will produce the unpleasant mildew smell.

- Compressor Cycles On and Off Rapidly: When the evaporator is leaking a large amount of refrigerant, the air conditioning system pressure will be dropping. The pressure sensor of the system is detecting this condition, and it is preventing the compressor to run to avoid damage, thus causing the rapid switching.

- Oily Mist from Vents: In the severe leaking condition, a small quantity of refrigerant oil will be discharged through the vent, forming an obvious oil film inside the windshield or a fine mist in the air.

How Long Does an AC Evaporator Last?

The air conditioner evaporator is essentially a tightly wound evaporator coil.Its purpose is to maximize the heat-exchanging surface area. In a controlled environment, these coils last 10 to 15 years with regular maintenance. Heavy-duty machinery operates in uncontrollable environments. Its evaporator’s service life is better measured in hours, not years.

Although the evaporator core is being designed with durability, its usage inside the bulldozer, the excavator, or the harvester is usually shorter than that inside the passenger vehicle. For the evaporators under heavy-duty operation, the actual expected service life is in the range of 8,000 to 15,000 hours. Some factors, which are specific to the job site, can cause its premature failure:

- Extreme vibration: The continuous severe vibration, which is generated by the engine running and traversing the rough terrain, during thousands of hours, will lead to stress fractures in the evaporator’s delicate aluminum tubes or in its welded joints, thereby resulting in leakage.

- Internal corrosion: This one is the invisible killer. If the moisture is entering the sealed air conditioning system (often during improper repair in the past), it will be reacting with the refrigerant and the oil to form corrosive acid. These acids are slowly corroding the evaporator from inside, and finally are creating the tiny pinhole leakage.

- External blockage and corrosion: The off-road environment is being full of dust, dirt, pollen, and other debris. If one neglects the cabin air filter of the vehicle, this debris will be sucked directly into the HVAC system, and there it will agglomerate, sticking to the wet evaporator fins. This thick layer of dirt not only insulates the core, preventing it from cooling the air, but also traps the moisture, thereby causing external corrosion and damaging the fins and tubes.

Average Cost to Replace an AC Evaporator

Understanding the AC evaporator replacement cost requires a detailed look at where the money goes. The overwhelming majority of the cost is not for the part itself, but for the highly skilled labor required to access it.

The Labor Component: A Deep Dive into the Process

The evaporator core is typically buried deep within the dashboard. To a technician, this is often a 6 to 10-hour job, depending on the machine. The process involves:

- System De-Pressurization: Connecting a specialized recovery machine to safely and legally reclaim all refrigerants from the AC system.

- Power Disconnection: Disconnecting the machine’s battery to prevent electrical shorts.

- Dashboard Disassembly: This is the most time-consuming step. It involves the careful removal of control panels, instrument clusters, radio and control modules, steering column components, and the entire dashboard structure.

- HVAC Unit Removal: Once the dash is out, the technician must disconnect heater hoses and AC lines from the engine bay before unbolting and removing the entire HVAC housing from the vehicle.

- Core Replacement: The HVAC housing is taken to a workbench and split open to finally access the AC evaporator. The old core is removed, and the new one is installed.

- Reassembly and Recharge: The entire process is performed in reverse. Once reassembled, the system is put under a vacuum to remove all air and moisture before being recharged with the precise amount of refrigerant and oil specified by the manufacturer.

The Parts Component: More Than Just the Core

A professional AC evaporator replacement involves more than just the evaporator itself. To ensure a lasting repair and honor a warranty, a shop will insist on replacing several related components.

| Cost Component | Estimated Price Range (Heavy Equipment) | Why It’s Necessary |

|---|---|---|

| Labor Cost | $420 – $600+ | Reflects 6-10+ hours of complex disassembly and reassembly at shop rates of $70-$100/hour. |

| Evaporator Core (OEM) | $180 – $400+ | OEM parts guarantee a perfect fit but come at the highest price point. |

| Evaporator Core (Aftermarket) | $80 – $145+ | High-quality aftermarket parts from trusted suppliers offer significant cost savings. |

| Receiver/Drier or Accumulator | $30 – $100+ | This part contains a desiccant that removes moisture from the system. It must be replaced any time the system is opened to the atmosphere. |

| Refrigerant & Oil | $60 – $150+ | The cost to fully recharge the system with the correct type and amount of refrigerant and lubricant. |

| Total Estimated Cost | $800 – $1,200+ | The final bill is a sum of all these parts plus the extensive labor. |

Factors That Affect AC Evaporator Replacement Cost

The final expense of this work maybe will differ to a great extent because of the following key factors:

- Machine Complexity: This is the greatest variable. To replace the evaporator on one simple skid steer loader with the basic dashboard is much quicker than to replace it on the modern combine harvester, which is equipped with a GPS display, complicated wiring harness, and precise decoration pieces. The higher the machine complexity, the more working hours are needed.

- Repair Shop Choice: The dealer of the manufacturer not only is possessing the highest labor rate, but also is possessing the most professional knowledge of your machine. The independent heavy equipment mechanic may provide a more competitive price.

- Parts Procurement (OEM vs. Aftermarket): As the table is showing, the choice of the parts is producing a significant influence. To select the OEM evaporator core instead of the high-quality aftermarket product, only this one choice may increase the bill by several hundred of dollars. But the quality aftermarket parts can save you more repair costs.

- Geographic Location: The labor rates in the different regions are differing in the very large manner.

Tips to Save Money on AC Evaporator Replacement

While this is an expensive job, you are not powerless. You can take proactive steps to control the cost.

- Get Multiple, Detailed Quotes: Do not accept a single verbal estimate. Contact at least two shops and ask for a written quote that breaks down the estimated labor hours, the cost of each individual part, and the price for the refrigerant service. This allows you to make an informed, apples-to-apples comparison.

- Source Your Own High-Quality Parts: This is the most powerful money-saving strategy. Repair shops add a significant markup to the parts they sell. You can purchase a top-tier aftermarket AC evaporator and the associated components (drier, expansion valve) from a reputable online supplier. Providing your own parts for the AC evaporator replacement can easily save you $200-$500 on the final bill.

- Bundle “While You’re In There” Repairs: The dashboard is already completely removed. Ask your technician to inspect the heater core and the blower motor. If these parts are old or showing signs of wear, replacing them at the same time costs only the price of the part itself, saving you from paying for the same 10 hours of labor again in a year or two.

- Evaluate the Repair’s True Value: On an older machine with high hours, a $2,000 repair bill can be a tough pill to swallow. It’s essential to take a step back and consider whether it is worth replacing your AC evaporator. Compare the repair cost to the machine’s overall value and its importance to your operation to make a sound business decision.

Final Thoughts

Without any doubt, replacing the air conditioning evaporator belongs to the category of great engineering work. According to the price in the market, under the conservative estimation, including labor costs, the estimated cost for replacing the AC evaporator is about $900 to $1,800. If you can understand the phenomenon of the failure, obtain the detailed quotation, make the strategic decision, and from one reliable supplier such as FridayParts to purchase the high-quality and price-reasonable aftermarket parts, then you can restore the comfort and the productivity of the machine cabin, without letting the repairing cost go beyond your budget.