When an off-road machine starts idling rough, losing pull under load, or running hotter than normal, we often chase fuel, turbo, or sensors first. But a failing EGR system can create the same headaches—plus it can push emissions and engine temps the wrong way. This guide breaks down bad EGR valve symptoms we can spot on excavators, tractors, loaders, and generators, what they usually mean (stuck open vs. stuck closed), and what to do before the problem turns into bigger downtime.

What Does the EGR Valve Do?

The EGR (Exhaust Gas Recirculation) valve controls how much exhaust gas is routed back into the intake/cylinders under certain operating conditions. The goal is simple: lower combustion temperature so the engine forms less NOx (nitrogen oxides). On many machines, proper EGR operation can also support fuel efficiency when the engine management system is working as designed.

In most modern off-road equipment, the EGR valve is mounted on or near the intake manifold or exhaust routing, and it’s commanded by the ECM. It opens and closes based on load, temperature, and other inputs. When it doesn’t move correctly—or when EGR passages plug with soot—we see the same pattern again and again: rough running, poor response, and heat-related issues.

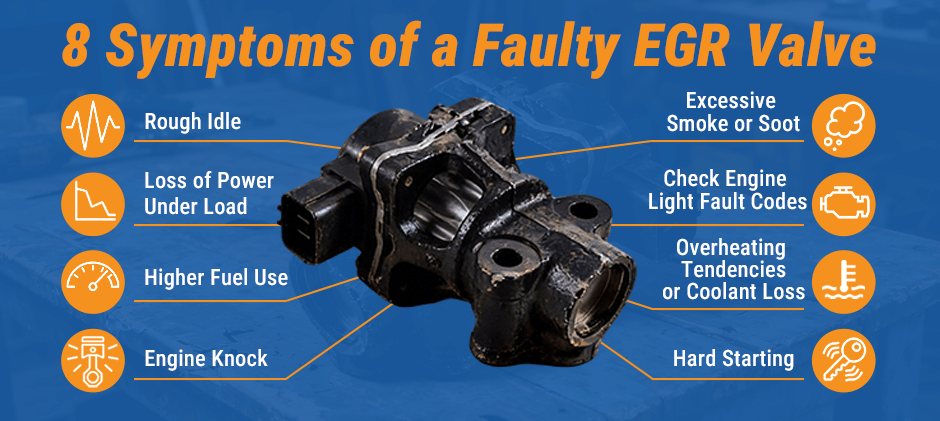

8 Common Symptoms of a Bad EGR Valve

Below are the eight most common bad EGR valve symptoms we see in off-road machinery. A key point: the same symptom can come from different causes, so we treat these as diagnostic clues, not a final verdict.

1) Rough idle or unstable low-RPM running

What it feels like: hunting RPM, uneven idle, vibration, or occasional stalling when the machine is warm or coming down to idle.

What it often means:

- Stuck open / leaking EGR valve can dilute the intake charge at the wrong time (too much exhaust at idle), which makes combustion unstable.

- Heavy soot buildup can also keep the valve from sealing.

Quick check: If your machine has live data, compare commanded vs. actual EGR position. If not, listen for idle quality changes after a controlled EGR test (where allowed by service procedures).

2) Loss of power under load

What it feels like: slower climb, weaker breakout force, sluggish hydraulic response because the engine isn’t holding RPM, or “flat” acceleration.

What it often means:

- A stuck-open can reduce the oxygen available for combustion when you need power.

- Stuck closed can raise combustion temps and trigger protective derates on some systems.

Why this matters for off-road machines: We don’t drive these at steady highway speed; we work them in cycles—dig, lift, push, regen events—so an EGR fault shows up fast as productivity loss.

3) Higher fuel use for the same work

What it feels like: you’re burning more fuel per shift, even with the same operator habits and job conditions.

What it often means: If EGR flow is wrong, the ECM may compensate with fueling changes. Incomplete combustion and poor efficiency can follow, especially if the valve is sticking and EGR flow becomes unpredictable.

Tip: Track fuel burn against hours and job type. Fuel “creep” is one of the most expensive bad EGR valve symptoms because it looks like a normal cost increase—until you compare month to month.

4) Engine knock/pinging

What it feels like: sharp rattling or knocking sounds when lugging, pushing, or snapping the throttle.

What it often means: A stuck-closed EGR valve can increase combustion temperature. Higher temps raise the risk of abnormal combustion events, which can sound like knock.

Important note: Knock-like noises can also come from injector issues or mechanical problems. If the noise is new and tied to load changes, treat it as urgent.

5) Excessive smoke or soot

What it looks like: darker exhaust during acceleration or load, sootier tailpipe, or faster soot loading in the aftertreatment system (where applicable).

What it often means: EGR faults can upset the air/fuel balance. Too much exhaust recirculation at the wrong time can reduce available oxygen and lead to incomplete burn, often seen as black smoke.

Operator-friendly clue: If smoke got worse at the same time power got worse, EGR flow problems move up the suspect list.

6) Check engine light, derate, or stored fault codes

What it looks like: MIL/engine icon, active diagnostic codes, reduced power mode, or forced idle/limited RPM depending on machine controls.

What it often means: The ECM detects EGR flow out of range, valve position errors, or related sensor signals not matching expected airflow.

How to do next: Pull codes and freeze-frame data if possible, then verify wiring/connectors and commands vs. actual operation before replacing parts.

7) Overheating tendencies or coolant loss

What it feels like: higher-than-normal coolant temp during steady work, temperature spikes in hot weather, or repeated need to top off coolant.

What it often means: The EGR system includes more than the valve. Many machines use an EGR cooler to reduce exhaust gas temperature before recirculation. FridayParts notes that a failing cooler can be caused by thermal stress, corrosion, or blockage; leaks can lead to coolant loss and white smoke, while blockages can restrict flow and contribute to overheating.

This is where we avoid tunnel vision: what looks like an “EGR valve issue” may be an EGR cooler issue—or both.

8) Hard starting, stumbling, or stalling after warm-up

What it feels like: longer crank, starts then dies, or stalls when transitioning between idle and load after the engine is hot.

What it often means: EGR that opens when it shouldn’t (or fails to close) can disrupt the mixture and airflow during the most sensitive moments—starting and low-speed transitions.

Rule of thumb: If the machine runs “okay” at higher RPM but acts up at idle/low RPM transitions, EGR sticking is a strong possibility.

Symptom-to-Cause Quick Guide

| Symptom | Likely EGR condition | Quick confirmation step | Risk if ignored |

|---|---|---|---|

| Rough idle | Stuck open / leaking | Compare commanded vs. actual EGR position | Stalls, unstable operation |

| Power loss | Stuck open or stuck closed | Check for derate + airflow mismatch | Lower production, higher cost per hour |

| Fuel use increases | Erratic EGR control | Trend fuel vs. hours; check codes | Higher operating cost |

| Knock/ping | Stuck closed | Check load-related noise + codes | Higher combustion temps, potential damage |

| Black smoke | Wrong EGR flow | Observe under load + inspect soot | Faster soot loading, poor burn |

| MIL/derate | Control or flow fault | Pull DTCs + inspect harness | Forced downtime if the derate escalates |

| Overheating/coolant loss | Cooler leak/blockage | Pressure test the cooling system | Escalates to major engine damage |

| Hard start/stalls | Stuck open/unstable control | Observe hot restart + idle transitions | Unplanned stops, safety risk on the jobsite |

Causes of a Bad EGR Valve

Most EGR valve failures on off-road machinery fall into a few practical buckets:

1. Carbon/soot buildup

Soot accumulation can restrict movement, block passages, or prevent a tight seal. Heavy-duty cycles, repeated low-load running, and frequent idle time can speed this up.

2. Sticking mechanism

If the valve can’t move smoothly, the ECM may command it correctly but not get the result it expects.

3. Electrical issues

Vibration, heat, and moisture are normal on equipment. A loose connector or damaged harness can mimic a valve failure.

4. Related system problems

A valve can be “fine” but still show bad EGR valve symptoms if the cooler is blocked, passages are restricted, or a sensor signal is wrong.

5. Harsh operating conditions

Dust, long hours, high load, and high heat are part of off-road life. These conditions increase thermal stress and contamination risk across the whole emission/exhaust system.

EGR Valve Maintenance Tips

We can’t eliminate soot, but we can reduce surprises and extend service life.

Practical habits that help

- Don’t ignore early derates or “new” rough idle. Small symptoms often become job-stopping faults.

- Inspect connectors and harness routing during routine service—look for rub-through, loose pins, and heat damage.

- Watch the coolant level and white smoke (especially if you suspect the cooler). Cooler leaks don’t fix themselves.

- Follow service procedures for cleaning if your maintenance plan allows it. Use the correct gaskets and torque specs.

- Document hours and conditions when symptoms appear. Dusty conditions + long idle time are useful contexts for diagnosis.

When it’s time to replace parts

If testing points to a hardware failure, it’s usually more cost-effective to replace the faulty component than to keep running and risk derating or overheating.

- To source the correct heavy equipment part, we can start with this EGR valve catalog page and match by machine/engine application.

- If overheating, coolant loss, corrosion, or blockage signs point to the cooler, this EGR cooler page is a useful place to confirm coverage and fitment for common off-road equipment.

If you’re doing the repair in-house and want a clear workflow, this step-by-step walkthrough for replacing an EGR valve can help you plan tools, downtime, and checks after installation (without guessing mid-repair).

Conclusion

Most bad EGR valve symptoms on off-road machinery include rough idle, loss of power, higher fuel consumption, smoke, or heat-related issues. The key is to confirm whether the valve is stuck, the control side is failing, or the cooler/passages are restricted—then fix it before derating or engine damage takes the machine out of service. With the right diagnosis and parts plan, we can protect uptime and keep operating costs predictable.