Spanner vs wrench, do they belong to the same thing? Is one better than the other? If using the wrong terminology, it may be causing ordering mistakes of the parts, and if using the wrong tool, then it may be causing the bolt to slip, leading to costly downtime. This guide will completely answer your confusion, explaining the main difference between them and helping you to exactly understand which tool you should be using on the working site.

What is Spanner and Wrench?

From the most basic level, both spanners and wrenches are tools for holding and turning fasteners (mainly nuts and bolts). They have a mechanical advantage. However, the definition and common use of these terms have very big differences, which mainly depend on the region you are in.

What is Spanner?

In British English and many other places in the world, “spanner” means a tool with a fixed jaw size. It fits a special size of nut or bolt. Since you cannot adjust it, it provides a very exact and strong grip, which reduces the risk of slipping and damaging the fastener. They usually are thinner and lighter than their adjustable counterparts.

What is Wrench?

In American English, “wrench” is a very big term, almost includes all tools that are used for turning fasteners. The thing that British people call a “spanner,” American people will call it a “wrench.” However, in these two places, the word “wrench” is also often used to describe the adjustable tool, for example, a pipe wrench or an adjustable spanner (in America, usually called a crescent wrench). These kinds of tools’ jaws can move to fit different-sized fasteners.

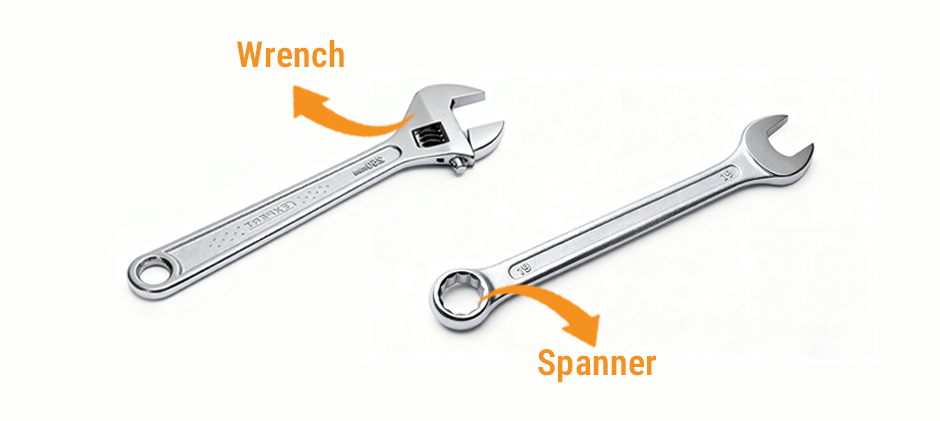

For the clarity of this guide, we will use the easiest-to-understand terms: “Spanner” means the tool with a fixed size, and “Wrench” usually means the tool that can adjust.

Common Spanner and Wrench Types

Your heavy equipment toolbox likely contains several variations of these tools, each designed for a specific task. Understanding the common wrench types is key to choosing the right one.

-

Combination Spanner (or Combination Wrench)

This is the workhorse of any mechanic’s toolkit. It features a U-shaped open end on one side and a closed-loop box end on the other, both for the same size fastener. The open end is quick for turning, while the box end provides a more secure grip for breaking loose or final tightening of bolts on engine mounts or frame components.

-

Adjustable Wrench (or Monkey Wrench)

This is the classic adjustable tool with one fixed jaw and one movable jaw controlled by a worm screw. Its main advantage is versatility, as one tool can handle multiple fastener sizes. However, its bulky head makes it difficult to use in tight spaces, and it has a higher risk of slipping if not adjusted tightly.

-

Torque Wrench

This is a precision instrument, not a standard turning tool. It is used to tighten a fastener to a specific torque (tightness) value. For critical components on off-road machinery, like engine head bolts, wheel lugs, or hydraulic pump mounts, using a torque wrench is non-negotiable to prevent component failure or warping.

-

Pipe Wrench

With its serrated, hardened jaws, the pipe wrench bites into round objects like pipes. On heavy equipment, operators might use it on large hydraulic piping, but they should exercise extreme caution, as its teeth can mar and damage the surface.

-

Spanner Wrench (Hook or Pin Spanner)

This is a specialized tool that doesn’t fit standard hexagonal nuts. A spanner wrench has a hook or a pin on its end designed to engage with notches or holes on a locknut, bearing retainer, or gland nut on a hydraulic cylinder. It is an essential tool for many specific repair jobs on heavy equipment.

Spanners vs Wrenches: The Main Difference

The core of the spanner vs wrench debate comes down to a simple trade-off: precision vs. versatility. This difference is rooted in their fundamental design and is the primary reason for the confusion in terminology. The main difference is geography—what one person calls a spanner, another calls a wrench. But functionally, the difference depends on whether you fix the tool or can adjust it.

Let’s break down the functional differences in a head-to-head comparison:

| Feature | Spanner (Fixed-Size Tool) | Wrench (Adjustable Tool) |

|---|---|---|

| Precision & Fit | Excellent. Designed for one size, providing a snug, 360-degree grip (box end) that minimizes slipping. | Fair. The adjustable jaw can have slight play, increasing the risk of slipping if not perfectly tightened. |

| Risk of Rounding | Low. The precise fit applies force evenly to the flats of the fastener, protecting its corners. | High. A loose fit can cause the tool to slip and “round off” the corners of a nut or bolt, making it very difficult to remove. |

| Speed & Efficiency | High. If you know the fastener size, you can work quickly without needing to make adjustments. | Low to Medium. You must stop and adjust the tool for every different-sized fastener, slowing down the job. |

| Versatility | Low. One spanner fits only one size. You need a full set to be prepared. | Excellent. A single adjustable wrench can cover a wide range of fastener sizes, both metric and imperial. |

| Access in Tight Spaces | Excellent. Spanners typically have a much slimmer profile, allowing them to fit into tight engine bays and around hydraulic lines. | Poor. The head of an adjustable wrench is bulky and often too wide for confined areas on machinery. |

Application Scope: Spanners vs Wrenches

Understanding the difference is one matter, the really important thing is knowing which time on the equipment each kind of tool.

When to Use a Spanner (Fixed-Size Tool)

When you know the fastener size and the situation requires precision and reliability, you should always default to using a spanner.

- High-Torque Applications: When you need to loosen a tight bolt or make final tightening, the firm gripping of an open spanner (for example, a combination wrench) is crucial for preventing slip and injury.

- Critical Components: For any part involving a hydraulic pipeline (using a flare nut spanner), brake system, or engine component, the precise fitting of a wrench can protect the fastener from damage.

- Confined Spaces: When working in a deep engine compartment or around transmission, the slim spanner is often the only suitable tool.

- Specialized Fittings: To adjust bearing preload or remove the hydraulic cylinder head, only the proper open spanner wrench can finish the work without causing damage.

Although the adjustable wrench has some shortcomings, it can still become an indispensable part of your hand tool collection.

When a Wrench (Adjustable Tool) Has Its Place

- Unknown size: When you are meeting a fastening piece of irregular hand tools, and also do not have a suitable wrench, the adjustable wrench can help you to settle down.

- Low torque task: When you deal with bolts that aren’t screwed especially tightly or assemble or disassemble non-critical components, you can use the adjustable wrench for a quick and convenient solution.

- Clamping nut: You can clamp the nut on the bolt’s back side while using a wrench or ratchet wrench to tighten the bolt’s other side.

Build Your Toolkit the Smart Way

In the final analysis, the difference between spanner and wrench is not in which word is more suitable, but in which kind of tool is more proper for the work at hand. For the professional maintenance of off-road machinery, you cannot do without a whole set of high-quality fixed-size spanners, while a movable wrench serves as a multifunctional backup tool. When you need to enlarge your toolbox, there is no necessity to pay the dealer’s price. FridayParts can provide affordable prices and high-quality products, and also possesses abundant stock, to ensure the wide compatibility with all your heavy equipment brands.