New Holland error codes and symbols are common terms for farmers, operators, and maintenance personnel. Knowing these code meanings is beneficial to finding the problems and coming up with solutions. This guide will give you a quick idea of what common error codes mean.

What Are New Holland Error Codes?

You can think of New Holland’s fault code as a reminder from the machine “the brain” (that is, the electronic control module, ECM). ECM monitors the operation of key components such as engines and hydraulic systems at all times. As long as there are sensor readings outside the normal range or a component doesn’t respond, the system generates a corresponding fault code. This code is equivalent to a machine telling you: “Something is wrong here.” The code will be displayed on the dashboard, and a corresponding warning symbol will light on. Learning to recognize the new Holland error codes is the first step in quickly identifying problems.

Common Types of New Holland Error Codes & Symbols

New Holland error codes and dashboard symbols let you know when something’s wrong.. There is a clear correspondence between the code and the symbols. This is the basis for machine diagnostics and operator alarm systems. When a machine breaks down, not just a single code is logged. It also tells you what’s wrong with audible alerts, text messages on the display, and, most intuitively, dashboard symbols. Symbols quickly display the problem type without being affected by language, while fault codes provide specific information for easy diagnosis and repair. Each error code corresponds to a different question and dashboard symbol, giving the operator a faster idea of the machine condition.

Engine Error Codes

The engine error codes were mainly the 3000 series. These codes are generated by the ECU (engine control unit) and are directly related to engine operation. They deal with engine performance, fuel systems and emissions systems, including fuel injection, air intake, cooling, lubrication, and emission control.

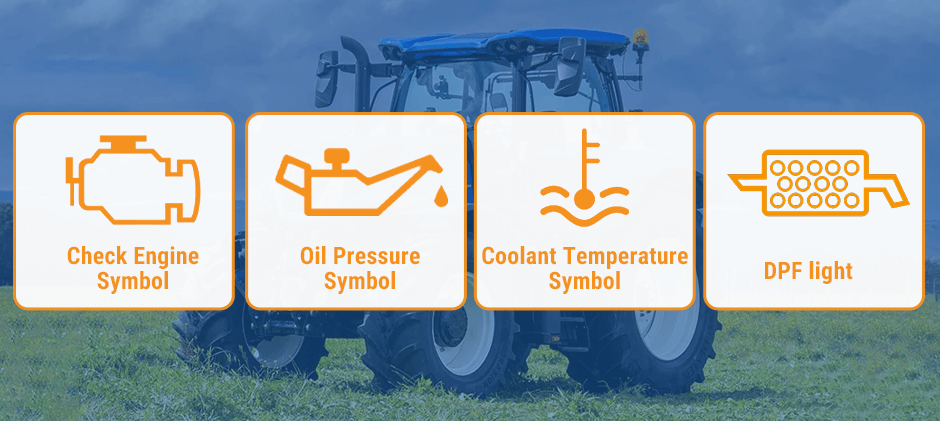

- Check Engine Symbol: This is a universal symbol, shaped like an engine block and usually amber. It lights up to some common problems, but it may not be that urgent.

- Oil Pressure Symbol: Looks like an old-fashioned oil jug shape. If the problem is serious, it will light up in red. It lights up to show that the oil pressure is too low or there is a problem with the pressure sensing circuit. For example, fault code 3028 (low engine oil pressure signal), this light goes on.

- Coolant Temperature Symbol: This light is like a thermometer immersed in a liquid, and will turn on red when the engine overheats. Overheating can be low coolant, a failing water pump, or a faulty temperature sensor.

- Emissions System Symbols: Modern tractors have symbols for the Diesel Particulate Filter (DPF) and Diesel Exhaust Fluid (AdBlue/DEF). These symbols will light up to indicate a need for regeneration, a low DEF level, or a fault within the after-treatment system.

Hydraulic System Codes

The main ones are 1000 series (rear lift/EDC), 4000 series (remote valve/EHR), 9000 series (front lift) and 10000 series (front axle suspension). These codes are all related to hydraulic systems, including lifting arms, hydraulic pumps, and related solenoid valve control.

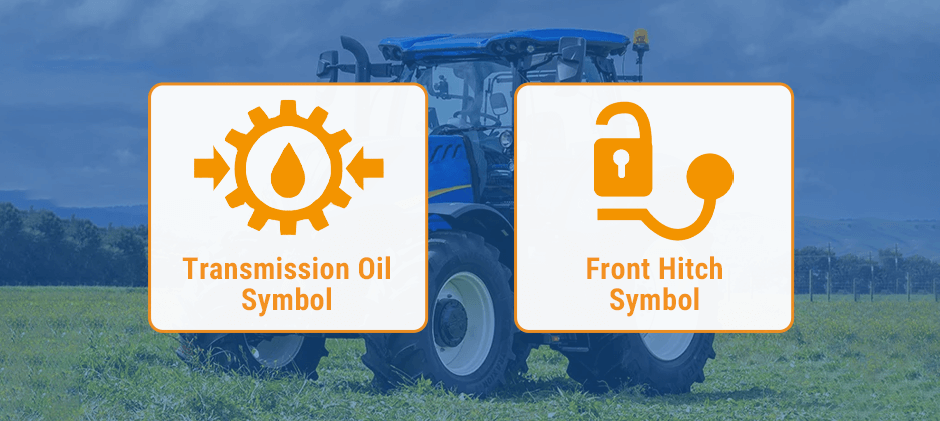

- Hydraulic/Transmission Oil Symbol: Usually a gear wheel with a drop of oil in the middle. This symbol is used to alert users to a problem with temperature or pressure in hydraulic or transmission fluid. Normally amber, it turns red when the problem is serious.

- Rear/Front Hitch Symbol: Three-point suspension like a tractor. This symbol lights up or flashes if something goes wrong with the electronic traction control (EDC) or position control system. A code like the 1000 series, like the position sensor fault code 1015, triggers this symbol.

Transmission Error Codes

It’s mainly the 2000 series. This series focuses on the transmission’s electronic control, covering problems with shifting, the clutch, or the drivetrain.

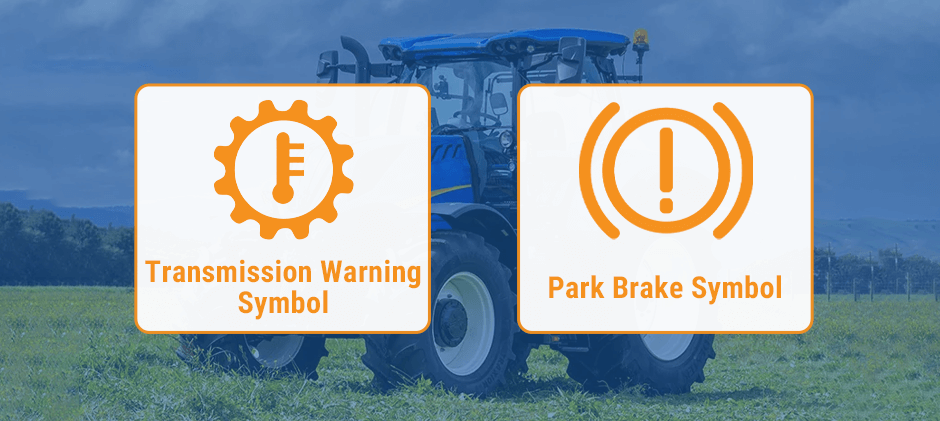

- Gear/Transmission Warning Symbol: The most common symbol is a gear icon, often with an exclamation mark inside. This indicates a general transmission fault. A code such as 2040 (clutch solenoid short circuit) will cause this symbol to light up, often in red or amber, and may cause the gear display to flash or go blank.

- Park Brake Symbol: While also a standard indicator, this symbol (a circle with a “P” or “!” inside) can flash or stay on if there is an electronic fault in the park brake circuit, preventing it from engaging or disengaging correctly.

Electrical System Codes

This type of code often points to more basic electrical problems. When these codes come, they can trigger fault codes for some other systems at once. Faults related to sensors, wiring, or control modules.

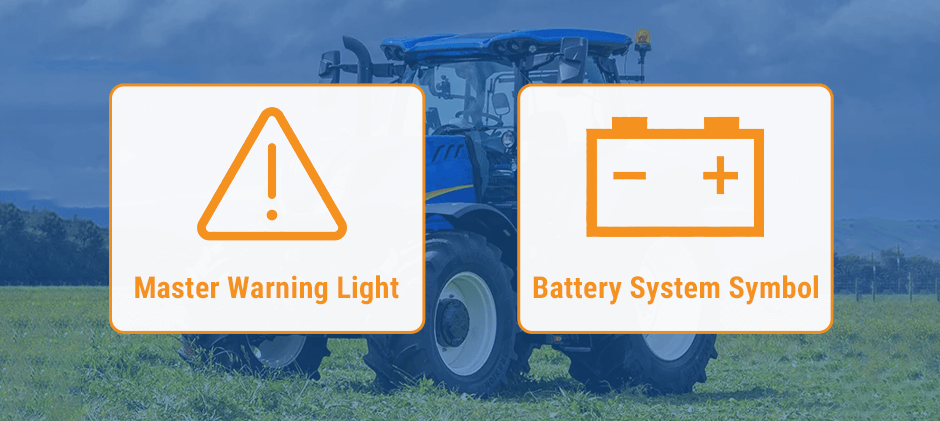

- Master Warning Light: This is the main light for many electrical faults, especially if there is a problem with the communication between control modules (CAN bus). It shows the machine is faulty. The specific fault code on the display needs to be checked.

- Battery/Charging System Symbol: The red battery icon indicates that there is a problem with the charging system. It could be a faulty alternator, a bad connection, or a general voltage issue.

Sensor Error Codes

This type of code is quite specific and points directly to a particular sensor. However, sensors often do not have their own unique symbols on the dashboard. Instead, a faulty sensor will trigger a warning symbol for its monitoring system. The logic of the machine is that if it cannot trust information from a sensor, it must declare a fault throughout the system that relies on that sensor.

- An engine oil pressure sensor fault (a 3000-series code) will illuminate the Oil Can symbol.

- A transmission speed sensor fault (a 2000-series code) will illuminate the Gear/Transmission symbol.

- A rear hitch position sensor fault (a 1000-series code) will illuminate the Rear Hitch symbol.

How to Use the New Holland Code List?

For a quick recovery to work, the key is to make proper use of fault-code information. Before you check the list, do these steps first to collect and analyze info. It’ll help you find the issue faster.

- Record all information: When the tractor breaks down, don’t just look at the code. Also note any symbols on the display, the color of the warning light (yellow or red), and what you were doing at the time—like lifting an implement, shifting gears, or starting the PTO.

- Make an Initial Diagnosis: using this list, based on the numbers in the code (for example, seeing 3xxx would tell it was an engine problem, seeing 1xxx would tell it was a rear hoist problem), quickly locate a possible faulty system.

- Analyze the Specific Description: Take a look at the code’s specifics, like “3006 – Coolant Temperature Signal – ABOVE NORMAL” (coolant temperature signal above normal, so you know where to look faster, like if there’s enough coolant, if the fan is spinning, whether the radiator is clogged, whether the water temperature sensor is broken, etc.

- Consult the Official Manual: Always consult your machine’s official Operator or Service Manual as the final authority. Only the official manual can provide the most accurate trouble code information and diagnostic steps for your specific model and serial number.

Wrapping Up

Finding out New Holland error codes and symbols can help you find the problem. At the same time, it saves a lot of time and money by preventing small faults from turning into big faults. If the code prompts that a part is worn or broken, it’s better to replace it as soon as possible.

For that, FridayParts offers a range of high-quality aftermarket parts at affordable prices. With many New Holland parts, you can find the right replacement sensor, filter, and more. Get your New Holland machine running smoothly now!

New Holland Code List

1000 Series

| Code | Description | Possible Common Causes |

|---|---|---|

| 1002 | Radar disconnected | The radar, which measures true ground speed for slip calculation, is not connected or its harness is damaged. |

| 1003 | Speed sensor error | An issue with the wheel speed sensor, which will affect slip control functionality. |

| 1006 | Slip control potentiometer signal too low | The knob for setting the desired slip percentage has a fault (short to ground or defective). |

| 1007 | Slip control potentiometer signal too high | The slip control knob has a fault (open circuit or defective). |

| 1008 | Raise / work switch failure | The main lift/lower control switch in the cab has failed. |

| 1009 | Both external switches operated at the same time | The two external fender-mounted hitch switches were pressed simultaneously, which is an invalid command. |

| 1010 | The height limit potentiometer signal is too low | The knob used to set the maximum lift height is shorted or defective. |

| 1011 | Height limit potentiometer signal too high | The height limit knob has an open circuit or is defective. |

| 1014 | R/H load sensing pin signal too low | The load pin on the right lift arm (for draft control) has an abnormal signal, likely disabling draft control. |

| 1015 | R/H load sensing pin signal too high | Same as above, but indicating an open circuit. |

| 1016 | L/H load sensing pin signal too low | The load pin on the left lift arm has an abnormal signal. |

| 1024 | Perform Hydraulic Lift Autocalibration | This is a very important prompt, not a fault. The system requires a calibration routine to be run, often after component replacement. |

| 1063 | Lower solenoid open circuit | The electrical circuit for the solenoid valve that lowers the hitch is broken. |

| 1064 | Raise solenoid open circuit | The electrical circuit for the solenoid valve that raises the hitch is broken. |

2000 Series

| Code | Description | Possible Common Causes |

|---|---|---|

| 2001 | ‘N’ – Shuttle too fast error | An attempt was made to shift from Forward or Reverse to Neutral while traveling at an excessive speed. |

| 2003 | ‘CP’ – Clutch pedal required | The system requires the operator to depress the clutch pedal to complete a shift or shuttle command. |

| 2012 | Clutch Pedal Potentiometer Signal too High | The clutch pedal sensor has a fault (open circuit or defective). |

| 2024 | Synchro clutches not calibrated | Extremely common. The transmission controller requires a calibration routine to be performed, usually after service or component replacement. |

| 2026 | Engine speed too high | A shift was attempted at an excessive engine RPM. |

| 2027 | Engine speed too low | A shift was attempted at too low of an engine RPM. |

| 2037 | Clutch Pedal switch open circuit | The switch at the bottom of the clutch pedal travel is not working, so the controller cannot confirm the pedal is fully depressed. |

| 2040-2045 | Clutch 1/2/3/4 solenoid short/open circuit | The solenoid controlling a specific powershift clutch pack has an electrical fault. |

| 2052 | Oil temperature sensor short circuit | Same as above, but a short circuit. |

| 2053 | 5 Volt Potentiometer Supply too High | The 5V reference voltage that powers various sensors is out of spec. |

| 2059 | Shuttle Lever switch disagree | The signals from the Forward, Neutral, and Reverse switches are contradictory. The controller cannot determine the operator’s intent. |

| 2076 | Flywheel Speed Sensor open circuit | The transmission controller is not receiving an engine speed signal. |

| 2077 | Flywheel Speed Sensor short circuit | Same as above. |

| 2091-2096 | C1/C2/C3/C4/High/Low Clutch not calibrated | Very common. Indicates that a specific clutch pack needs its fill time calibrated for smooth engagement. Failure to do so results in harsh or delayed shifts. |

3000 Series

| Code | Description | Possible Common Causes |

|---|---|---|

| 3001 | Accelerator Pedal Signal – NOT PLAUSIBLE | The two signals from the accelerator pedal do not match, so the ECU cannot determine the true throttle position. |

| 3002 | Accelerator Pedal Signal – SOURCE HIGH | The accelerator pedal sensor signal voltage is too high (open circuit). |

| 3003 | Accelerator Pedal Signal – SOURCE LOW | The accelerator pedal sensor signal voltage is too low (short circuit). |

| 3006 | Coolant Temperature Signal – ABOVE NORMAL | Engine is overheating. This will likely cause the engine to derate or shut down. |

| 3018 | Boost Pressure Signal – ABOVE NORMAL | Turbocharger is producing excessive boost pressure. Could be a stuck wastegate or control issue. |

| 3028 | Oil Pressure Signal – BELOW NORMAL | CRITICAL WARNING! Engine oil pressure is dangerously low. Shut down the engine immediately and investigate. |

| 3029 | Oil Pressure Signal – SOURCE HIGH | The oil pressure sensor has an open circuit. |

| 3030 | Oil Pressure Signal – SOURCE LOW | The oil pressure sensor has a short circuit. |

| 3049 | Battery voltage signal – ABOVE NORMAL | System voltage is too high. Check the alternator/regulator. |

| 3060-3083 | Injector solenoid valve Cylinder (1-6) – FAULT | The electrical part of a specific cylinder’s fuel injector has a fault. Will cause a misfire, smoke, and rough running. |

| 3102 | Fuel pressure monitoring CP3 – ALL OTHER FAULTS | The high-pressure fuel pump (CP3) is not building the commanded rail pressure. Common causes: clogged fuel filters, leaks in the system, or a failing pump. |

| 3104 | Fuel pressure signal – SOURCE HIGH | The rail pressure sensor has an open circuit. |

| 3117 | ECU: Self Test Shutoff Paths ( Start Up ) – NOT PLAUSIBLE | The ECU detected that the previous shutdown was improper (e.g., power was cut via battery disconnect). May cause an engine derate. |

| 3128 | Hand Throttle potentiometer diff. error. | The two signals from the hand throttle potentiometers do not agree. |

4000 Series

| Code | Description | Possible Common Causes |

|---|---|---|

| 4001 | Signal of Aux-stick (AUX1) out of range low | The paddle or joystick for remote valve #1 has a fault. |

| 4040 | Supply Voltage too low | The armrest controller or remote valve module is not receiving enough voltage. |

| 4042 | Arm Rest Module (ARU) CAN ‘Bus off’. | CRITICAL FAULT. The main armrest controller has lost communication with the vehicle’s CAN bus. All armrest functions will be disabled. |

| 4044 | Controller Fault (Flash Memory) | The controller’s internal program memory is corrupt. |

| 4045 | Controller Fault (Data Memory) | The controller’s internal data memory (e.g., calibration values) is corrupt. |

| 4100 | Remote No.1 No control Message Received | The #1 remote valve module is not receiving commands over the CAN bus from the armrest controller. |

| 4106 | Remote No.1 Spool movement too low | The controller commanded the valve spool to move, but it did not travel the expected distance. Could be a stuck spool or faulty position sensor. |

| 4109 | Remote No.1 Manually operated | The manual override lever on the valve body has been activated, disabling electronic control. |

| 4170 | EHR Control No. 1 not calibrated | Very common. The remote valve requires a spool travel calibration, typically after replacing the valve or controller. |

| 4184 | EHR Joystick potentiometer X open circuit. | The X-axis (left/right) of the hydraulic joystick has a failed sensor. |

| 4190 | No communications from (EHR) No.1. | The main vehicle controller has completely lost communication with the #1 remote valve module. |

5000 – 10000 Series

| Code | Description |

|---|---|

| 5008 | Rear PTO solenoid circuit overcurrent |

| 5024 | Rear PTO not calibrated (Common) |

| 5034 | Rear fender PTO switch open / short to ground. |

| 5036 | Rear PTO failure to Start |

| 6020 | FWD switch error |

| 6023 | FWD solenoid open circuit |

| 7014 | Difflock switch error |

| 7017 | Difflock solenoid open circuit |

| 7024 | Steering angle sensor not calibrated (Common on models with auto FWD/Diff) |

| 8024 | Front PTO not calibrated (Common) |

| 8036 | Front PTO failure to Start |

| 9001 | Front HPL (High Pressure Lift) Potentiometer open circuit. |

| 9002 | Front HPL (High Pressure Lift) Potentiometer short circuit. |

| 10004 | Front Axle Potentiometer above threshold |

| 10005 | Front Axle Potentiometer below threshold |

| 10024 | Front Suspension not calibrated (Common) |

14000 Series

| Code | Description | Possible Common Causes |

|---|---|---|

| 14011 | Engine speed sensor short to VCC or open circuit | The instrument cluster is not receiving an engine speed signal. |

| 14015 | The ADIC 5 volt reference voltage is too low | The instrument cluster’s own 5V power supply for sensors is faulty. |

| 14051 | Fuel level sensor short to VCC or open circuit | The fuel gauge is not working due to a faulty sender or wiring. |

| 14082 | Engine oil pressure short to Ground or open circuit | The instrument cluster is not receiving an oil pressure signal. |

| 14200 | EEPROM error | The internal memory of the instrument cluster (which stores hours, settings) is corrupt. |

| 14900 | Transmission module missing (DA/DB/DE/DF). | CAN Bus Fault. The instrument cluster cannot communicate with the transmission controller. |

| 14901 | Engine controller not present (EDC7) | CAN Bus Fault. The instrument cluster cannot communicate with the engine controller. |

| 14904 | Arm Rest Module (ARU) missing. | CAN Bus Fault. The instrument cluster cannot communicate with the armrest controller. |

15000 Series

| Code | Description | Possible Common Causes |

|---|---|---|

| 15001 | Exceeding safe operating wheel speed (10 km/h) | The system was active when the tractor speed exceeded the safety limit. |

| 15002 | Steering wheel control proximity sensor open circuit. | The sensor that detects the operator’s hand on the wheel has failed. |

| 15008 | Change valve Solenoid open circuit | The solenoid that switches between normal and fast steering modes has an electrical fault. |

| 15010 | Safety switch Fail | A redundant safety switch in the system has failed its self-test. |

| 15015 | Cold oil, temperature below 5 degrees C. | The system is disabled because the hydraulic oil is too cold for safe operation. |

| 15024 | System not calibrated. | The Fast Steer system requires calibration after installation or service. |