When a P0037 code lights up your dashboard on a heavy-duty on-road truck, it signals that your aftertreatment system isn’t working as it should. But this issue is fixable when you know where to look. In this article, we’ll explain what Code P0037 means, why it happens, and how to repair it effectively. We’ll also touch on rare cases where similar issues might appear in non-road equipment powered by similar Tier 4 Final engines. Suppose you own or operate heavy trucks or specialized off-road machinery with emission-controlled diesel engines. In that case, this guide is designed to help you avoid downtime, reduce fuel consumption, and prevent unnecessary part replacements.

Table: Quick Reference for Heavy-Duty Technicians

| Code | Affected Sensor | Location | Primary System | Common Root Cause |

|---|---|---|---|---|

| P0037 | oxygen sensor (Heater Circuit) | Bank 1 Sensor 2, after the catalyst | Emission System | Open heater circuit / low voltage |

| SPN 3251 FMI 3 | Equivalent J1939 fault | Downstream O2 or NOx sensor | Aftertreatment | Poor wiring, blown fuse |

| P2205 | NOx Sensor Heater Circuit | Post‑SCR sensor | DEF System | Heater short‑to‑ground |

What Does Code P0037 Mean?

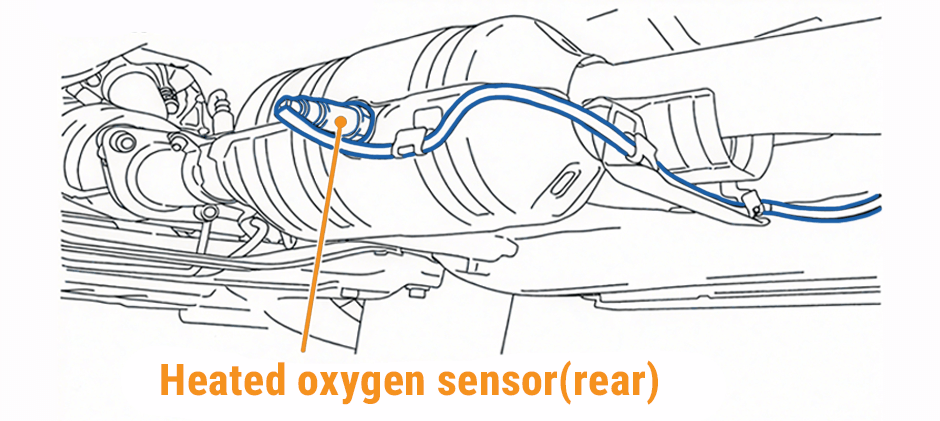

The P0037 code stands for Heated oxygen sensor (HO2S) Heater Control Circuit Low – Bank 1 Sensor 2. Simply put, the electronic control module (ECM) has detected low voltage in the heater circuit of the downstream oxygen sensor, the one located after the diesel oxidation catalyst or catalytic converter.

This sensor continuously measures oxygen content in exhaust gases to help the ECM fine-tune the air‑fuel ratio and manage aftertreatment regeneration.

Because the oxygen sensor must operate at a precise temperature (often 600 °C or higher), it contains a heater element. If this circuit reads a lower voltage than expected, the ECM logs code P0037.

While this failure is most common on on‑road trucks with OBD‑compliant ECMs, similar sensor heater circuit issues may occasionally appear on non-road machinery equipped with Tier 4 Final or Stage V engines that share automotive‑style diagnostics.

What are the Causes of the P0037 Code?

Understanding why code P0037 appears helps you select the correct fix instead of replacing parts blindly. Common sources include:

| Possible Cause | Description |

|---|---|

| Faulty Heater Element | The heating resistor inside the downstream oxygen sensor is open or shorted. |

| Blown Fuse | A fuse protecting the O2 heater circuit has failed, typically due to an overvoltage event. |

| Poor Ground Connection | Corrosion or broken ground wires lead to voltage drops and “circuit low” readings. |

| Damaged Wiring Harness | Melted insulation, chafed connectors, or moisture can cause shorts to ground. |

| ECM Driver Failure | Rare, but the ECM’s internal transistor that controls the heater may fail. |

| Exhaust Heat Damage | On older trucks, sensor wires too close to hot pipes can burn and interrupt current flow. |

A downstream oxygen sensor in a heavy diesel engine usually fails from vibration and thermal cycling. After thousands of hours, the internal heater can burn out the same way a light bulb filament does.

How to Fix Error Code P0037?

Fixing a P0037 code isn’t one‑size‑fits‑all—it depends on what caused the fault. Here’s a practical approach most fleet technicians use:

1. Inspect the Sensor Connector:

Disconnect the downstream oxygen sensor plug. Look for moisture, melted pins, or corrosion. Clean and reseat connectors firmly.

2. Check Fuses and Grounds:

Use a multimeter to verify heater‑circuit fuse continuity and a solid ground path to the chassis.

3. Measure Sensor Resistance:

Remove the sensor and measure the heater terminals. A normal range is typically 3 – 10 Ω. Infinite resistance means the heater is open.

4. Check for Short‑to‑Ground or Voltage:

With the ignition ON and the sensor unplugged, you should see 12 V at the heater‑power wire. Any constant zero indicates an open fuse or broken wire.

5. Replace the Faulty Sensor:

If the resistance or voltage test fails, replace the oxygen sensor. Use anti‑seize on threads and tighten per the service manual specification.

6. Clear the Code:

Reset the P0037 code using an OBD‑II or J1939 service tool. Run the engine and monitor data to verify circuit voltage returns to normal.

Quick tips: Do not simply replace sensors without verifying circuit integrity—many P0037 callbacks are caused by a broken ground or fuse, not the sensor itself.

Mid‑article tip: aftermarket suppliers like FridayParts carry high‑quality oxygen sensors designed for heavy‑duty trucks and some Tier 4 off‑road engines. Each sensor meets OEM specs but comes at a fraction of dealership cost, ensuring accurate readings and faster warm‑up performance.

How to Diagnose P0037?

Diagnosis should follow a logical path that separates component faults from wiring or ECM issues. Here’s a checklist that aligns with professional fleet maintenance standards:

1. Confirm the Fault:

Clear all existing codes, warm the engine, and see if code P0037 returns. If it doesn’t, it might have been a temporary voltage drop.

2. Visual Inspection:

Trace the harness from the downstream oxygen sensor to the ECM. Look for melted, rubbed, or pinched wires, especially near the exhaust.

3. Perform a Voltage Drop Test:

Measure voltage between heater‑power feed and chassis ground under load. Anything over 0.2 V indicates resistance from a weak connection.

4. Check Engine Control Module Output:

Using a scan tool, command the O2 heater ON and monitor voltage. If power and ground are good but the current draw is absent, suspect a burned heater.

5. Cross‑Compare with Other Sensors (Optional):

If available, monitor data from upstream and downstream sensors. A downstream heat‑up delay beyond 90 seconds often confirms a failed heater.

Technicians also check service bulletins. Some truck ECMs flag code P0037 only after prolonged cold‑start cycles, meaning the heater circuit simply needs heavy‑gauge connectors cleaned or re‑torqued—a minor task that prevents downtime.

Additional Considerations for Off‑Road and Tier 4 / Stage V Engines

Modern off‑road machines powered by Tier 4 Final engines often share similar exhaust aftertreatment layouts. While most use the SPN/FMI diagnostic format instead of OBD “P‑codes,” a heater‑circuit‑low fault could mirror P0037 behavior. In other words, whether it reads SPN 3251 FMI 3 or P0037, the problem points to the same heater circuit of an exhaust oxygen sensor or NOx sensor.

That means the repair logic stays the same: test voltage supply, grounds, and sensor resistance before replacing components. These sensors are mission‑critical for precise dosing of DEF and for keeping regeneration cycles short.

Preventing Future Oxygen Sensor Heater Failures

Routine maintenance can prevent another P0037 code from showing up:

- Keep wiring looms away from turbo or DPF heat.

- Replace aging connectors with weather‑sealed types.

- Check for rusted ground lugs during oil changes.

- Use dielectric grease on every oxygen sensor connector.

- Always torque new sensors to spec to prevent exhaust leaks.

Remember: downstream sensors communicate constantly with the ECM. Even a small heater resistance deviation can create a false alarm, so electrical cleanliness is critical.

Final Summary

A P0037 code might look like a minor electronic fault, but left unchecked, it can cause fuel waste and downtime for fleets that depend on precise emission control. The fix is usually straightforward—clean wiring, replace the faulty oxygen sensor, reset the code, and get your truck or Tier 4 machine back on schedule. If you need reliable replacement sensors, FridayParts offers a wide selection of aftermarket oxygen sensors designed for heavy-duty engines. You’ll get OEM-level performance at an affordable price and quick global shipping. Restore full efficiency with a quality part upgrade today.