Engage the PTO at low engine RPM, then raise RPM to the rated speed. Most “PTO problems” come from engaging too fast, being in the wrong range/mode, or a safety interlock stopping activation. This practical guide explains how to engage the PTO on a John Deere tractor step by step, covers common switch/lever styles, and lists quick fixes when the John Deere PTO won’t engage.

“Idle down, engage, then throttle up.”

What To Check Before Engaging PTO?

Safety checks prevent broken parts and injuries. Confirm the implement is rated for your PTO type (rear/mid) and speed (commonly 540 or 1000 RPM), and make sure all PTO shields/guards are installed.

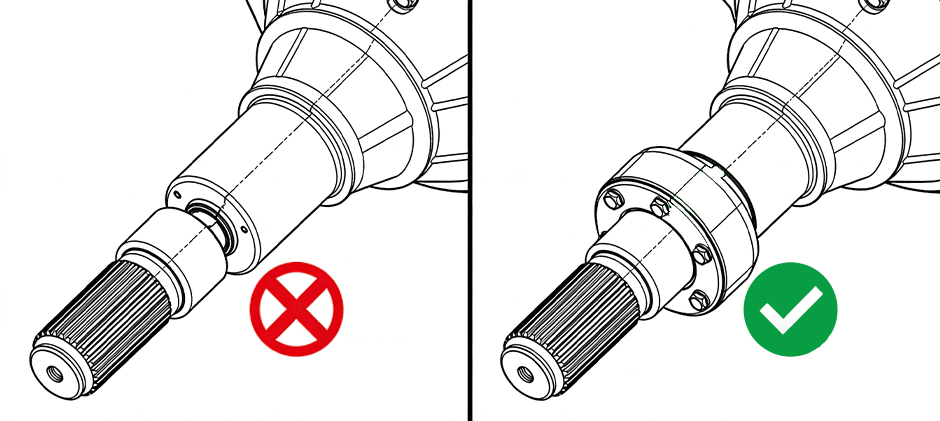

Attachment setup must be correct. Verify the driveline is fully seated/locked on the tractor stub and implement input, the height/angle is reasonable, and nothing is binding during lift or turns.

Clear Statement: A correctly connected driveline is more important than extra horsepower. If you are unsure about your specific setup, check our guide on how to choose the right PTO shaft for your tractor.

What Type Of John Deere PTO Do You Have?

Your PTO control style changes the exact steps. Many John Deere tractors use either a mechanical lever (often older models) or an electro-hydraulic switch/knob (common on compact and utility models).

What Is An Independent PTO?

Independent PTO can run even when the tractor isn’t moving. This is common on modern tractors and is typically controlled by a PTO switch plus safety interlocks.

What Is A Transmission PTO?

Transmission PTO speed depends on clutch/gear engagement. If you press the clutch or stop the transmission, the PTO may stop too (model-dependent).

Clear Statement: If you’re unsure which PTO you have, treat it as “independent + safety interlocks” until you confirm in the operator’s manual. If you need to identify your specific machine year or specs, use our John Deere serial number lookup guide.

8 Steps To Engage PTO On John Deere Tractor

These steps work for most rear PTO systems. Small differences exist by model, but this sequence fits the intent behind searches like “how to engage pto on john deere tractor.”

Step 1: Start With A Clear Area

People and pets must be away from the implement. PTO-driven tools can throw debris and pull loose clothing fast.

Step 2: Sit In The Operator Seat And Fasten The Belt (If Equipped)

Seat switches can prevent PTO engagement. Many John Deere models require an operator present for PTO activation.

Step 3: Set Engine Speed To Low Idle

Low idle reduces shock load. Engaging at high RPM can snap shear pins, damage gearboxes, or twist a driveline.

Step 4: Put The Transmission In Neutral Or Park (If Needed)

Neutral/park helps the PTO engage smoothly. This also reduces load if the implement starts under resistance.

Step 5: Disengage The PTO First (Confirm “Off”)

Starting from “Off” avoids partial engagement. If the PTO indicator light is on or flashing, reset it to off and wait a moment.

Step 6: Engage The PTO Control (Lever Or Switch)

Engage smoothly and deliberately. On switch-type PTOs, pull/turn as required; on lever PTOs, move through the detent without forcing.

“If it won’t click/engage, don’t force it—find out why.”

Step 7: Let The Implement Spin Up At Idle

Let it stabilize for a few seconds. Listen for abnormal knocking, grinding, or violent vibration.

Step 8: Increase Throttle To Rated PTO Speed

Bring RPM up to the correct PTO speed, not “full throttle by default.” Use the tach/PTO mark if available, and match what the implement requires.

Clear Statement: Smooth engagement is cheaper than repairs.

When To Use A Clutch While Engaging PTO?

Use the clutch only if your model requires it. Some John Deere transmission-PTO setups need clutch coordination, while many independent PTO systems do not.

If you’re unsure, choose the gentle option. Reducing engine RPM and minimizing load is always correct, even if clutch use varies.

Why Won’t My John Deere PTO Engage?

A safety interlock is the most common cause. Seat switch, PTO guard switch (if equipped), neutral switch, or brake/park interlock can block PTO activation. If you suspect a switch issue, you might need to check for ignition switch problems or wiring faults.

Electrical and hydraulic issues are also common. A blown fuse, bad PTO switch, faulty solenoid, low hydraulic oil, or low system pressure can prevent the PTO clutch pack from applying. Learn how to check hydraulic fluid on your John Deere tractor to rule out fluid levels as the cause.

Mechanical failures are less common but more expensive. Worn PTO clutch packs, damaged PTO brake, stripped splines, or a failed gearbox can stop output even if the light says “on.”

“If the PTO light is on but the shaft doesn’t turn, suspect driveline connection or internal PTO clutch/brake issues.”

7 Symptoms Of Unsafe PTO Engagement

These symptoms usually mean load or engagement problems. Stop and inspect before continuing.

- Grinding or clunking when engaging

- PTO stalls the engine immediately at idle

- Burning smell or hot PTO area (possible clutch slip)

- PTO speed surges or won’t hold under load

- Vibration or wobble in the driveline

- PTO turns even when “off” (possible brake drag issue)

- Clicking/ratcheting noises near the PTO output

Clear Statement: Noise during PTO engagement is a warning, not a “break-in.”

How To Disengage PTO Safely?

Disengage at low RPM whenever possible. Throttle down, switch/lever PTO off, and wait for a complete stop before dismounting or adjusting the implement.

Never “step over” a rotating driveline. Wait until all motion stops and verify visually.

6 Tips To Extend PTO Lifespan

Good habits prevent driveline and PTO clutch damage. Use these as a quick maintenance mindset.

- Engage at low idle and spin up gradually

- Grease driveline joints per the implement schedule

- Keep shields installed and replace cracked guards

- Check hydraulic oil level/condition (for PTO clutch pressure)

- Avoid extreme driveline angles while running

- Fix small vibration early before it becomes spline wear

Summary

Engaging a John Deere PTO is simple: idle down, engage smoothly, then throttle to rated PTO speed. If the PTO won’t engage, check safety interlocks, electrical power (fuses/switch), and hydraulic oil/pressure before assuming a major failure. When you’re replacing worn driveline components or upgrading for reliability, browse FridayParts for a compatible PTO shaft that fits your tractor and application.