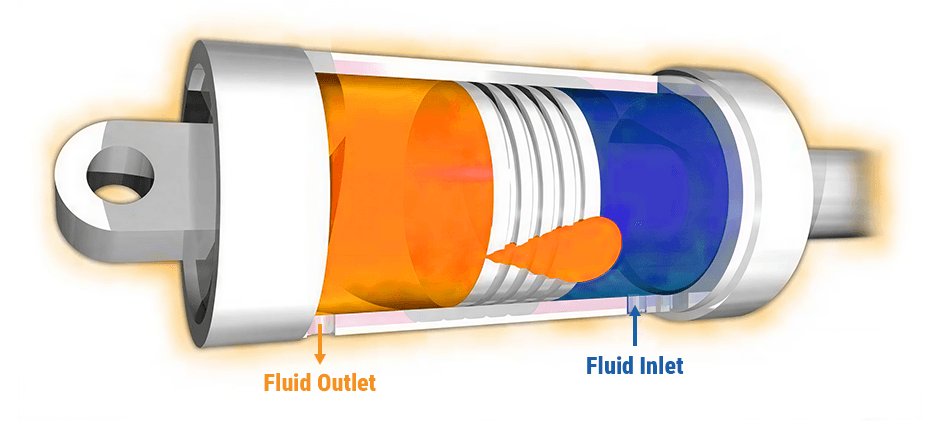

Internal leakage in a hydraulic cylinder refers to the unintended flow of hydraulic fluid from one side of the piston to the other. This usually occurs due to aging or damaged seals or problems with the piston itself. Because this leakage happens internally, it is not visible to the naked eye. However, when internal leakage occurs, hydraulic fluid leaks, leading to pressure loss and reduced overall system efficiency. Below, we will discuss how to check if a hydraulic cylinder is leaking internally.

How to Check If a Hydraulic Cylinder Is Leaking Internally?

An internal leak, also known as a bypass leak, occurs when high-pressure hydraulic fluid leaks from one side of the piston to the other. Generally, it is because the piston seal in the hydraulic cylinder barrel fails. Unlike an external leak, you won’t spot a single drop of oil on the floor. Instead, you’ll feel it in how the machine runs: slow or jittery movements, can’t hold a load steady, and just an overall weak feel. This hidden efficiency drain can sap 15–20% of your system’s power before you even notice there’s a problem. Before you start tearing parts apart, there are a few simple diagnostic checks you can run.

The Temperature Test

This method usually quickly identifies the problematic hydraulic cylinder. Start the machine and let the hydraulic fluid reach normal operating temperature first, then fully extend or retract the hydraulic cylinder you suspect and hold it against the joystick for a while. This way the system will continuously add high-pressure oil to one side of the piston.

If the piston seal is leaking, hydraulic fluid will slosh back and forth inside the cylinder, creating friction and heat. At this point, touch the outside of the cylinder barrel—watch out, don’t burn yourself! The leaking cylinder will feel way hotter than the others, especially right where the piston sits.

If you want to judge more accurately, you can also use an infrared thermometer to measure it. A difference of 5 –10℃ between the suspect cylinder and the normal cylinder will basically determine that there is an internal leak.

The Drift and Disconnect Test

If you want to distinguish whether it is an internal leak in the cylinder or a leak in the control valve, you can take the excavation motor arm as an example. Let me emphasize first that safety must come first. This test is done with the boom raised, and the boom must be supported mechanically.

Lift the boom off the ground a bit, secure it with a sturdy support block or bracket, and then turn off the engine to allow the pressure in the system to slowly remove. Then find the two oil pipes on the lifting cylinder, remove the oil pipe connected to the piston rod side, and place a bucket under it to catch the oil.

After the oil pipe is removed, people slowly move the bracket supporting the boom away. At this time, the focus is on two things: how to move the boom and whether there is oil flowing out from the cylinder interface.

- The boom sinks while oil continues to flow out of the cylinder interface, indicating that the cylinder piston is sealed and leaking.

- The boom sinks, but there is almost no oil coming out of the interface, which means the cylinder is fine, but the control valve is leaking.

The Pressurized Flow Test

You can check for internal leaks with this test—no need to take the cylinder apart at all. Let’s use an excavator bucket curl as an example.

Park the machine and set the bucket flat on the ground, steady and solid. Then disconnect the hydraulic hose on the bucket cylinder that’s responsible for retracting the cylinder (the one that makes the bucket open up). Aim the hose end into a clean bucket to catch oil.

Start the machine and slowly work the control lever to extend the cylinder and curl the bucket. But since the bucket’s pressed against the ground, the cylinder can’t actually move—this forces the system to build full pressure on one side of the piston.

If the piston seal is shot, high-pressure fluid will leak past it and flow steadily out of the disconnected hose into your catch bucket. A little spurt at the start is totally normal—that’s just the residual oil moving through the line. But if oil keeps flowing steadily nonstop? Then you know for sure the cylinder has an internal leak.

Hydraulic Fluid External Leak vs. Internal Leak

Before you call it an internal leak, make sure to rule out an external one first. Misdiagnosing this can cost you big bucks on repairs you don’t even need. The difference is super simple: you can see an external leak, but you can only feel an internal one. External hydraulic leaks are totally obvious. You’ll spot oil seeping, dripping, or even spraying out of some part. They’re easy to find, but you gotta fix ’em right away—otherwise you’ll lose fluid and mess up the whole system with contaminants.

| Component to Inspect | Indication of External Leak | Probable Cause |

|---|---|---|

| Rod Seal (at Gland) | A visible film of oil on the extended piston rod; drips forming on the gland nut. | Worn or damaged rod seal or wiper seal. |

| Hose Fittings | Fluid weeping or dripping at the crimp or threaded connection points. | Damaged O-ring, improper torque, or cracked fitting. |

| Port Connections | Oil accumulating around where the hoses connect to the cylinder barrel. | Failed port seal or a crack in the weld. |

If you suspect a leak that’s seeping slowly and hard to spot, add a little manufacturer-approved fluorescent dye to the hydraulic fluid. The machine runs for a while and then uses a UV flashlight to find the leak point.

The internal leak does not see the oil, but the machine behaves incorrectly:

- The boom, boom, or bucket slowly falls down on its own

- Obviously weak, what used to be able to be lifted is now impossible to lift

- The movements are not smooth, a little dull and weak

- The hydraulic oil temperature is higher than usual

Regular Maintenance & Best Practices

If you want to have fewer problems with hydraulic cylinders, the best way is to prevent them in advance.

- Daily inspections: Watch the piston rod for dents or scratches, as these minor injuries can wear down the seal. Check for loose joints and any signs of fluid leakage.

- Protection against dust sealing ring: The dust seal on the end of the cylinder head can block dust, dirt and moisture. Keep the piston rod clean.

- Keep hydraulic fluid clean: Be sure to use the ISO grade oil recommended by the machine manufacturer. Dirty or spoiled fluid will accelerate the wear of internal components. Remember to check and change the hydraulic fluid and filter regularly.

- Filters are important: The filter can filter out small particles that may scratch the cylinder wall. Time-sensitive filter changes are key. If the filter is clogged, the oil may bypass the filtration and flow directly into the system, allowing dirty oil to flow around.

Replacing Hydraulic Cylinder Seals and Parts

Check the hydraulic cylinder is leaking internally; most likely the piston seal is broken. Remove the cylinder and replace all seals. By the way, check to see if there is any wear on other hydraulic cylinder parts. It is very likely that the seal damage is caused by these parts. Buy the parts you need in the FridayParts one-stop shop and we are committed to helping you maintain the highest standards of quality and safety in your operations.