Checking and maintaining proper track tension on a Bobcat excavator is one of the most effective ways to extend the life of your undercarriage parts, prevent costly downtime, and maintain smooth operation on any job site. The right tension keeps the track in sync with sprockets and rollers, preventing wear and energy loss. In this guide, we’ll show you step by step how to check and adjust your Bobcat excavator parts for ideal track performance.

Why Check and Adjust Track Tension?

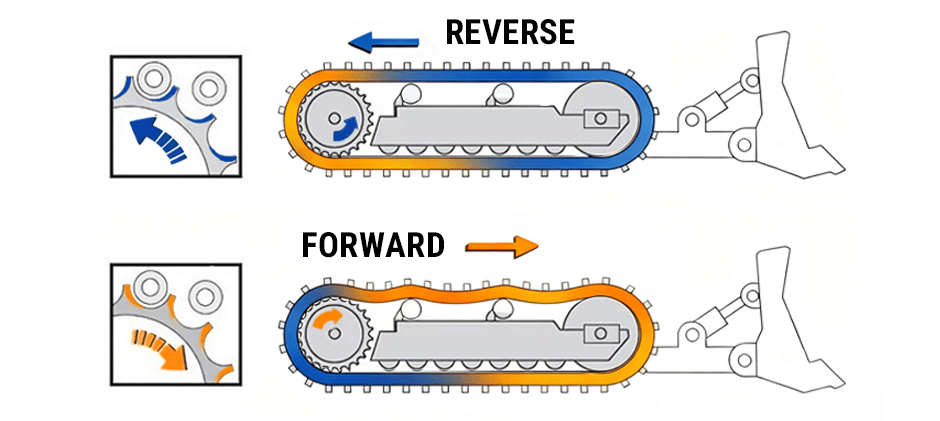

The tracks are the foundation of your machine — they handle weight, provide traction, and maintain balance on rugged surfaces. If your excavator tracks are too loose, they can derail or slip off the sprocket, especially on muddy or uneven ground. If they’re too tight, pressure builds within the track assembly, wearing down the idlers, rollers, and drive motor prematurely.

For heavy-duty Bobcat models working in demanding environments, correct track tension is more than comfort — it ensures power transmission efficiency and mechanical reliability. Regular inspection and adjustment save on undercarriage parts costs and prevent sudden breakdowns that halt job progress.As skilled operators often said, “Loose tracks shorten productivity; tight tracks shorten component life. The right balance saves them both.”

How To Check Bobcat Excavator Track Tension?

Adjusting track tension isn’t complicated, but it demands precision and attention to safety. Follow these steps to ensure your Bobcat excavator is correctly tensioned.

1. Park and Prepare the Machine

- Park the machine on a flat, level surface to prevent slipping.

- Lower the bucket and arm until the boom can lift one side of the track slightly off the ground — about 3 inches is ideal.

- Use jack stands on both ends of the track frame for added stability, ensuring no contact with the track itself.

This process allows the track to hang freely, giving accurate sag measurements — an essential indicator of track health.

2. Measure Track Sag

Use a steel measuring tape or a simple ½‑inch (13 mm) bolt or block as a reference. Measure the distance between the bottom of the track frame and the top of the track shoe at the lowest point between the rollers (the middle roller area is most accurate).

Replace and re‑measure if debris, mud, or stones affect the reading. Over time, track links stretch — measuring regularly helps identify wear before it causes operational damage.

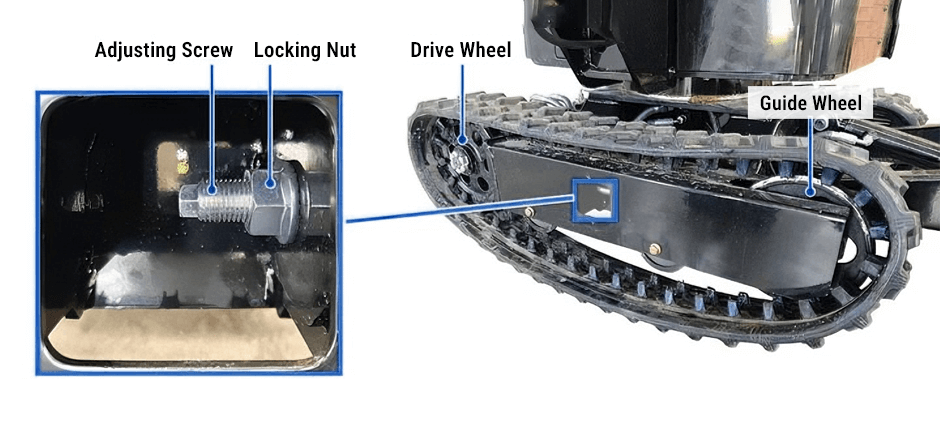

3. Adjust Track Tension — Add or Release Grease

On most Bobcat excavator parts, tension is controlled by a grease-filled adjuster cylinder.

To Tighten:

- Remove the track frame’s access cover to locate the grease fitting.

- Use a grease gun to add grease slowly.

- Stop when your reference bolt or dowel fits snugly at the specified sag range.

To Loosen:

- Attach a bleed tool to the relief fitting.

- Gently turn it counterclockwise (no more than 1½ turns).

- Release grease pressure until the sag matches the recommended range.

- Tighten the bleed fitting securely and replace the access cover.

Notice: Always wear safety glasses and gloves. The system holds high-pressure grease, which can cause injury if the fitting is removed completely.

By following these steps, you’ll maintain ideal track alignment and protect surrounding undercarriage parts, such as rollers, sprockets, and tension cylinders.

How Often to Check Track Tension?

Tracking conditions vary by workload and terrain, but tension should be checked:

- Every 10 operating hours — for machines working in mud, sand, or gravel.

- Every 50 hours — for general operation under stable ground conditions.

- After each cleaning or washdown, since debris and water reduce the grease consistency.

You should also inspect tension before long hauls or heavy-load tasks. New tracks may require more frequent checks during the first 100 hours of use as they stretch slightly before stabilizing. Periodic adjustments help prevent over-tightening — a common cause of premature undercarriage parts failure in compact excavators.

Maintenance Frequency and Performance Table

| Work Environment | Check Interval | Recommended Action | Additional Notes |

|---|---|---|---|

| Mud, clay, or loose sand | Every 8–10 hours | Clean & inspect tension | Frequent washdowns shorten grease life |

| Gravel or rock terrain | Every 20 hours | Check wear on rollers & sprockets | Replace worn track shoes early |

| General-purpose use | Every 40–50 hours | Standard tension check | Maintain grease cleanliness |

| Long storage periods | Before restart | Re-grease and tension check | Grease can compress over time |

Common Mistakes in Track Tension Adjustment

Even experienced operators can miscalculate tension or overlook small details that create expensive damage later. Below are the most frequent errors to avoid:

1. Skipping Regular Checks

Operators often focus on engine maintenance and ignore the tracks until a problem occurs. This neglect leads to uneven wear, especially on older machines or replacement Bobcat excavator parts.

2. Adjusting to Uneven Ground

Always test and measure on firm, level terrain. An angled surface distorts track sag readings and can result in over-tightening.

3. Adding Too Much Grease Too Quickly

Rapid pumping builds excess pressure beyond safe limits, risking track seal failure and potential injury.

4. Ignoring Undercarriage Debris

Packed dirt, stones, or snow can change tension readings. Always clean the undercarriage before any maintenance.

5. Using Incorrect Measuring Tools

A small difference of a few millimeters can affect the operation. Use solid metal dowels or certified gauges, not flexible cables or unverified spacers.

Regular inspection combined with accurate tools ensures your Bobcat excavator stays balanced and efficient on all terrains — from compact soil to rocky construction sites.

Better Maintenance, Longer Life!

Maintaining your Bobcat excavator means more than occasional cleaning — it’s about precision and consistency. Proper tension preserves your drivetrain, increases operating speed, and ensures even wear on the entire track assembly. Over time, that reliability translates into cost savings and fewer unplanned service calls. FridayParts provides premium aftermarket Bobcat excavator parts — from tracks to adjuster cylinders — offering OEM‑quality fit, fast delivery, and cost-effective solutions for all your heavy equipment needs. Check your track tension today and rely on FridayParts to keep your excavator moving tomorrow.