When we’re running off-road machinery, the cab is where we spend the longest hours—and where dust, pollen, smoke, and fine grit try to follow us in. A neglected cabin air filter doesn’t just make the cab smell bad; it can cut vent airflow, slow defrost, and make the HVAC system work harder than it should. In this guide, we’ll pin down when to replace it, how often to plan for it, the big mistake that can turn a simple swap into a blower problem, and practical habits that keep your air filter life predictable.

When Should You Change the Cabin Air Filter?

Most operators don’t “see” the cabin air filter doing its job, so we replace it based on symptoms + hours + conditions, not hope. For off-road equipment (excavators, skid steers, wheel loaders, dozers, telehandlers, tractors), these are the clearest signs the filter is past its useful life:

The most common signs

- Reduced airflow from vents even when the fan is on high

- Musty or dusty odors when the HVAC starts

- More dust is settling inside the cab than normal

- Foggy windows that take longer to clear (defrost feels weak)

- More allergy-like irritation during long shifts in dusty seasons

What these symptoms mean mechanically

A clogged cabin air filter restricts incoming air. Your blower has to work against higher resistance, which can:

- Reduce airflow across the evaporator/heater core (comfort drops fast)

- Keep moisture lingering in the cab (fogging and odors)

- Increase the chance that debris ends up where you don’t want it during removal (we’ll cover that in the “big mistake” section)

Cab air and engine intake are separate systems. If your machine feels down on power or fuel use creeps up, check the engine air filter too. Clogged or low-quality engine intake filtration can drop engine power up to 12% and increase fuel use by 8%—costs that show up every day in heavy dust.

How Often to Change Cabin Air Filter?

There’s no single hour interval that fits every job site. A machine working in fine dust all day will load a cabin air filter much faster than one on soft ground with light debris. So we use a base interval and then adjust by environment.

A practical replacement plan

Below is a planning table we can use across mixed fleets. Treat it as a starting point—your operator manual and site conditions win if they differ.

| Work conditions | What we usually see in the cab | Suggested check frequency | Typical replacement trigger |

|---|---|---|---|

| Light dust, seasonal use, closed cab most of the day | Mild dust film, no odor | Every 250 hours | Replace when airflow drops or at seasonal service |

| Moderate dust (grading, loading, farm field work) | Noticeable dust, vents feel weaker | Every 150–250 hours | Replace at the first airflow drop or odor |

| Heavy dust (dry earthmoving, demolition, and cleanup, sweeping) | Dust builds quickly, and filters look gray fast | Every 50–150 hours | Replace proactively on schedule |

| High smoke/pollen season (regional wildfire haze, spring pollen) | Odor, irritation, fogging | Every 100–200 hours | Replace when odor/irritation starts, even if it “looks OK.” |

Off-road machines often idle, run in short cycles, and work in bursts of extreme dust. Calendar reminders miss that. If your machine runs long shifts, log hours and tie filter checks to the same routine you use for greasing and walk-arounds.

You can also stock up on enough replacement air filters, cabin air filters, or engine air filters to easily replace any faulty air filters when needed.

From the provided FridayParts catalog guidance:

- Cabin replacements are often a low-cost job; cabin air filter prices range roughly $5.4 to $600, depending on the model.

- Broad filtration prices can range widely (about $8.2 to over $1,000) based on type/spec.

That widespread is exactly why we plan by equipment model and work conditions instead of guessing.

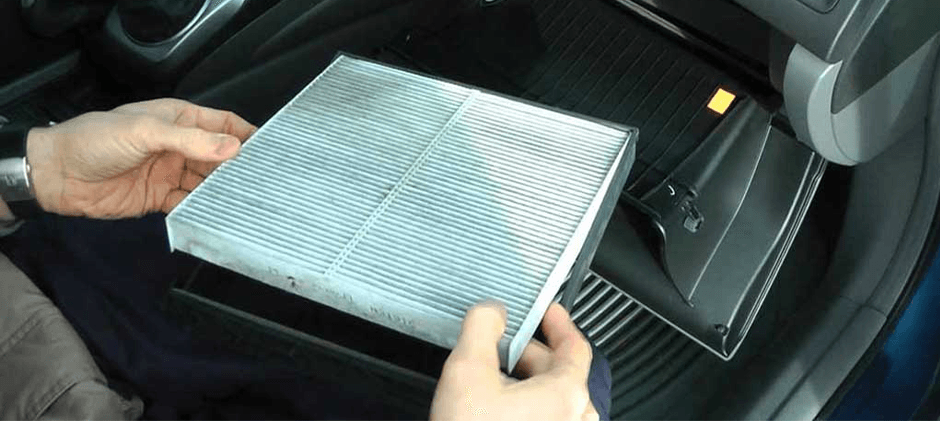

One Big Mistake to Avoid When Changing

The biggest avoidable mistake is letting debris fall into the blower housing during removal—especially when the cabin air filter sits horizontally and collects leaves, pine needles, and grit over time. Once debris drops into the blower:

- Best case: you get annoying noise and vibration

- Worst case: debris damages the blower wheel or jams the motor

- Worst case: you’re chasing airflow problems that look like “HVAC failure” but started as a messy filter swap

How do we avoid it

- Run the fan for a moment before shutdown (helps dry moisture that holds debris)

- Open the access panel slowly and keep the filter level

- Vacuum the housing edge first before pulling the filter out

- Slide the filter into a bag as it comes out, if it’s packed with debris

- Wipe and inspect the sealing surfaces so air can’t bypass the new filter

If you want a clean, step-by-step walkthrough for the swap itself, this guide is a good companion: a quick DIY replacement walkthrough. (We still recommend matching the exact access method to your equipment model, since layouts vary.)

Two other mistakes that cause repeated problems

- Installing the filter backward (many filters have airflow arrows; reversing can reduce performance)

- Forcing the wrong size so it buckles—air will leak around it and carry dust into the cab

If you’re deciding between types (standard vs higher-efficiency media, odor control, etc.), this buying-focused explainer helps you choose based on how and where you work: a practical buyer’s guide for selecting the right filter.

Tips to Maintain Your Cabin Air Filter

Replacing filters is normal. Replacing them too often usually means we can improve how the cab is managed. These tips are aimed at off-road machinery realities: open doors, dusty boots, frequent in-and-out, and harsh sites.

1) Use recirculation smartly in heavy dust

When working in heavy airborne dust, recirculation can reduce how much new dusty air gets pulled through the cabin air filter. The tradeoff is humidity and fogging risk, so we balance it:

- Use recirc during the dustiest passes

- Switch to fresh air periodically to control moisture and keep the defrost effective

2) Keep cab door seals and intake areas clean

A perfect cabin air filter can’t help if the cab leaks like a sieve.

- Inspect door seals and latches

- Clear debris around HVAC intake grilles

- Avoid pressure washing directly into intake areas

3) Don’t “blow out” a used filter as a routine fix

Compressed air can tear media or open pinholes you can’t see. If the filter is loaded enough that you want to blow it out, it’s usually time to replace it. A damaged cabin air filter may look fine, but pass fine dust.

4) Set a simple inspection habit

We’ve found the best maintenance is the one we actually do. Try this cadence:

- Every 50–100 hours: quick airflow/odor check

- Every 150–250 hours: pull and inspect (more often in heavy dust)

- Any time airflow drops or defrost weakens, inspect immediately

5) Maintain engine intake filtration, too

Cab comfort and engine power are different systems, but they show up in the same place: our productivity. FridayParts highlights that engines can pull huge volumes of air, and restricted intake can cut power and raise fuel use. If your machine is dusty, planning both the cab and engine air filter checks together reduces missed intervals and surprise downtime.

6) Keep spare filters on hand for peak season

Dust season and harvest season don’t wait for shipping. Keeping 1–2 spare cabin air filter units per machine class avoids “run it one more week” decisions that lead to miserable shifts and foggy glass.

Conclusion

For off-road machinery, replacing the cabin air filter is one of the simplest ways to protect comfort, defrost performance, and HVAC efficiency in dusty work. We get the best results by tying replacement to operating hours and site conditions, avoiding debris drops into the blower, and keeping seals and intake areas clean. When it’s time to buy, FridayParts offers a wide selection as an aftermarket parts supplier—high-quality products at affordable prices, vast inventory, and wide compatibility for many heavy equipment brands.