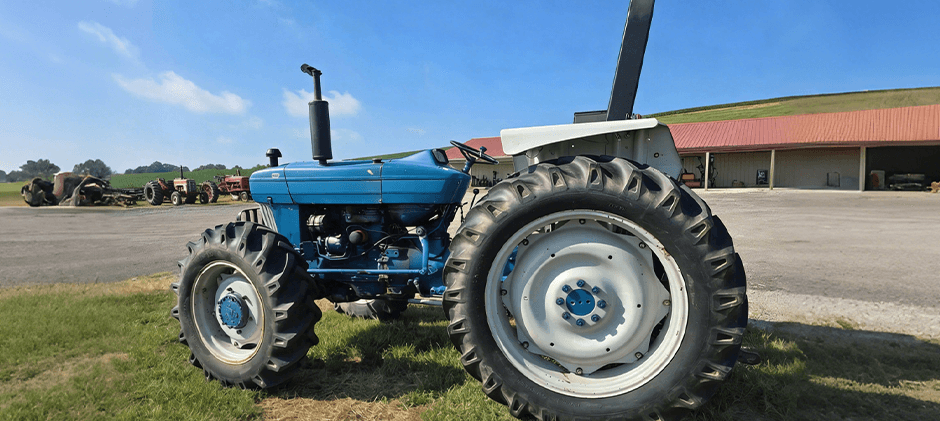

Among the most respected models in the compact category is the Ford 1500. Produced for only a few years, this machine has earned a lasting reputation for its durability and straightforward design. For owners, whether you’re restoring a family heirloom or relying on it for daily chores, understanding your Ford 1500 inside and out is the key to keeping it running for decades to come. This guide is your central resource for that knowledge. We’ll explore what makes this tractor special, dive deep into its maintenance needs, troubleshoot common problems, and guide you toward finding the right parts to ensure its longevity.

About the Ford 1500 Tractor

Manufactured by the Japanese company Shibaura for Ford from 1979 to 1982, the Ford 1500 was a direct response to the growing demand for powerful yet nimble compact tractors. It wasn’t designed with flashy features or complex electronics. Instead, its purpose was singular: to be an accessible, dependable tool for a variety of tasks. Its enduring popularity is a testament to the success of that philosophy.

- Mechanical Simplicity: In an age of computer-controlled everything, the 1500 is refreshingly analog. It features a gear-driven transmission and a straightforward mechanical PTO engagement. This design means there are fewer complex systems to fail and that most repairs and maintenance tasks can be performed by a mechanically inclined owner with standard tools.

- A Fuel-Sipping Powerplant: At the heart of the Ford 1500 is the Shibaura LEK802, a two-cylinder liquid-cooled diesel engine. While its 23-horsepower rating may seem modest, this engine is known for producing excellent torque at low RPMs, making it ideal for tasks such as tilling, mowing, and light loader work. Most importantly, it is exceptionally fuel-efficient, allowing you to get more work done on a single tank.

- Surprising Versatility: Equipped with a standard Category 1 three-point hitch and a 540 RPM rear PTO, the Ford 1500 can operate a wide range of implements. From brush hogs and finish mowers to post-hole diggers and small balers, this tractor can handle the core needs of any small property. Available in both 2WD and 4WD configurations, the 4WD models are particularly sought after for their superior traction in mud, snow, and on hilly terrain.

Ford 4000 Tractor Specifications

Engine Detail

| Shibaura LET862C diesel 2-cylinder liquid-cooled |

– |

|---|---|

| Displacement | 69.2 ci 1.1 L |

| Bore/Stroke | 3.35×3.94 inches 85 x 100 mm |

| Power | 19.8 hp 14.8 kW |

| Air cleaner | oil bath |

| Pre-heating | glow plugs |

| Compression | 21:1 |

| Rated RPM | 2500 |

| Starter volts | 12 |

| Oil capacity | 4.5 qts 4.3 L |

| Coolant capacity | 5.6 qts 5.3 L |

Transmission

| Type | gear |

|---|---|

| Gears | 12 forward and 4 reverse |

| Oil capacity | 21 qts 19.9 L |

Dimensions

| 2WD Wheelbase | 60.2 inches 152 cm |

|---|---|

| 4WD Wheelbase | 59.3 inches 150 cm |

| Length | 110.2 inches 279 cm |

| Width | 50.5 inches 128 cm |

| Height (ROPS) | 84.3 inches 214 cm |

| Height (exhaust) | 75.2 inches 191 cm |

| 2WD Weight | 2144 lbs 972 kg |

| 4WD Weight | 2305 lbs 1045 kg |

| 2WD Ground clearance | 13.8 inches 35 cm |

| 4WD Ground clearance | 12.6 inches 32 cm |

| 2WD Front tread | 41.3 to 43.3 inches 104 to 109 cm |

| 4WD Front tread | 39.8 inches 101 cm |

| Rear tread | 41.3 to 47.3 inches 104 to 120 cm |

Source from: www.tractordata.com

Ford 1500 Tractor Maintenance Essentials

With the Ford 1500 tractor, steady maintenance is less about fancy diagnostics and more about preventing the common cascade: small leak → low fluid → heat → wear → expensive repair. The tractor’s age also means seals and rubber parts are often living on borrowed time, even if the machine has low hours.

Here’s how we approach a maintenance routine that fits real off-road use (mowing, loader work, light tilling). Instead of chasing a perfect schedule, we focus on inspection points that catch problems early:

What we inspect first

- Fluid condition and level: engine oil, coolant, transmission/hydraulic oil. Milky fluid suggests water contamination; burnt smell points to heat and friction.

- Air intake path: A restricted air filter can make a small diesel feel tired and smoky under load.

- Fuel system hygiene: old tanks collect debris; water in diesel shows up as rough running or hard starts.

- Cooling system: clean radiator fins and verify hoses aren’t soft, cracked, or bulging.

- Hydraulic function under load: lift arms that drift down or hesitate can indicate internal leakage, air, or a weak pump.

- Front axle and steering (especially 4WD): look for wetness around hubs and knuckles, torn boots, and looseness that points to wear.

Why do leaks matter more on older compact tractors?

A modern machine may tolerate small seepage for a while because it has tighter filtration and often better heat management. On an older compact tractor, a seep at a fitting or a damp axle area can quickly become a real problem because the system capacity isn’t huge, and because contamination (dust + oil film) accelerates wear.

A practical rule we use is: if a leak can fling oil onto a rotating part, it’s not “minor.” That includes axle areas, PTO seals, and anything near the clutch housing.

Consumables and service parts that usually pay off

Even if your Ford 1500 “runs fine,” these items tend to be the best return on money and time because they stabilize the tractor:

- Filters (engine oil, fuel, air)

- Hoses and clamps that show age

- Battery and starting circuit connections

- Hydraulic suction/return sealing points (to prevent aeration)

- Wear items used heavily with loaders (clutch-related adjustments and inspection)

Common Issues & Solutions

Most Ford 1500 tractor problems fall into a few repeat categories: cold-weather behavior, PTO engagement complaints, hydraulic lift issues, and 4WD front axle seepage. The key is to diagnose by symptom and narrow the cause before buying parts. We’ve seen a lot of owners replace “the obvious part” only to find the root issue was adjustment, contamination, or a worn sealing surface

Symptom-based troubleshooting table

| Symptom you notice | Common root causes | What do we check before ordering parts |

|---|---|---|

| Hard shifting when cold | Oil viscosity is too heavy; the clutch is not fully releasing; the linkage needs adjustment | Correct fluid type for ambient temp; pedal free-play; linkage bind |

| PTO grinds or is hard to engage | PTO clutch wear; linkage out of adjustment; operator engagement technique | Linkage adjustment; clutch condition; verify mechanical engagement movement |

| 3‑point lift hesitates, chatters, or feels weak | Air in system; restricted filter; worn pump; internal leakage in lift circuit | Fluid level/condition; filter; suction leaks; bleed procedure after service |

| Lift drifts down under load | Internal hydraulic leakage (piston/seal wear in cylinder/lift circuit) | Load test; check for bypass symptoms vs external leaks |

| Wetness at 4WD hubs/knuckles | Front axle seal wear, bearing play, and shaft wear groove | Confirm axle type; inspect sealing surface; check bearing preload/play |

| Steering feels loose or wanders | Tie-rod/ends wear; steering box wear; front axle pivot wear | Check free play; inspect joints; verify wheel bearing tightness |

Recommended Parts & Upgrades

When you’re ready, we can build a parts plan around how you actually use your Ford 1500 tractor—mowing, loader work, or seasonal property maintenance. In most cases, the best “upgrade” isn’t cosmetic; it’s restoring sealing, filtration, and wear items so the machine starts cleanly, holds hydraulic pressure, and doesn’t shed oil at the front axle.

Conclusion

The Ford 1500 remains a practical compact off-road tractor because it’s simple, serviceable, and capable with the right maintenance. If you keep fluids clean, fix leaks early, and use the serial number to confirm configuration, you can avoid most repeat failures—especially hydraulic drift and front axle seepage. As an aftermarket parts supplier, we support these repairs with high-quality products at affordable prices, a vast inventory, and wide compatibility across many heavy equipment brands.