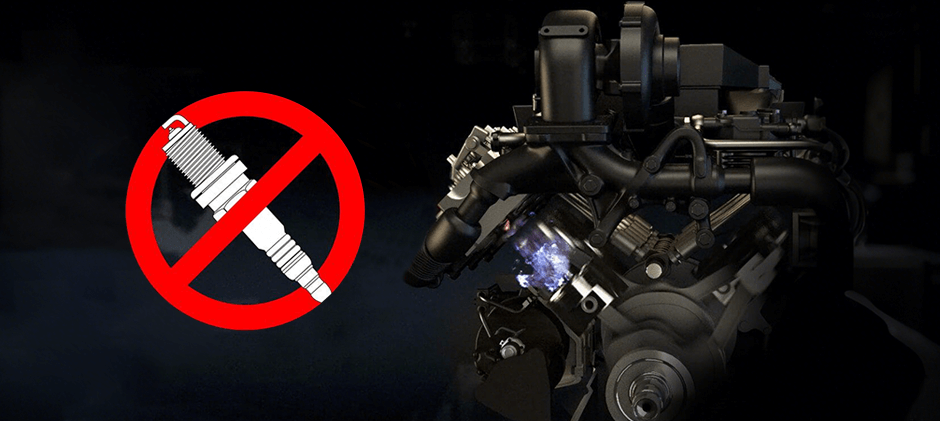

If you’ve worked on a gasoline engine, you know spark plugs are what ignite the fuel. But pop the hood of a diesel engine — haven’t you wondered, do diesels have spark plugs?

The short answer is no. If this question has crossed your mind, this detailed article is here to break it down. We’ll use simple language (only necessary jargon included) to keep things easy to follow. No long, tangled sentences — just natural, varied wording that’s straightforward to read.

What are Spark Plugs?

Why don’t diesel engines have spark plugs? Let’s talk about how spark plugs work in a gasoline engine. The gasoline engine draws in gasoline and air. The piston compresses the mixture. But these mixtures will not burn on their own, which requires a fire source. The spark plug is for ignition. It fires a spark through high voltage electricity, igniting the mixture and making the engine generate power.

How Diesel Engines Work?

Diesel engines, the workhorses of the heavy equipment world, achieve combustion through a completely different and more forceful method. This process is the core reason they are built for high torque and grueling work cycles. It all comes down to the physics of pressure and heat.

Compression Ignition vs. Spark Ignition

The key distinction is that the fuel is ignited. As stated earlier gasoline engines utilize spark ignition. They function at compression ratios generally ranging from 8:1 to 12:1. The air temperature alone is insufficient for ignition. Therefore, they depend on the spark plug to initiate combustion.

Diesel engines operate using compression ignition. The engines in heavy equipment feature higher compression ratios, typically between 17:1 and up to 22:1. As the piston moves upward it compresses the air into a confined area. Compressing a gas this much causes its temperature to increase rapidly. In a diesel engine the air temperature can surpass 1,000°F (540°C) due, to compression. This heated air acts as the ignition source. A fine, atomized mist of diesel fuel is injected directly into this hot air, and it ignites instantly without any spark.

Glow Plugs in Diesel Engines

This is a point where misunderstandings may occur. Although diesel engines lack spark plugs a number of them come with glow plugs. It is important to know that glow plugs and spark plugs have different functions. A glow plug does not ignite; it acts as a heater.

A glow plug is a heating component, similar to the coil, in an electric stove but significantly stronger. Its tip, crafted from metals can reach temperatures exceeding 1,800°F (1,000°C) within a few seconds. Its only function is to help start the engine in conditions. When you switch the key in your excavator on a morning the glow plugs engage first warming the air and the metal surface of the combustion chamber. This initial heat ensures that even when the engine block is cold, the compressed air can reach the auto-ignition temperature of the diesel fuel. Once the engine is running and has built up its own operational heat, the glow plugs are no longer needed for the combustion process.

Why Diesel Engines Don’t Need Spark Plugs?

The absence of spark plugs in a diesel engine isn’t an oversight; it’s a result of a fundamentally different engineering philosophy designed for power, efficiency, and durability. Several key factors make spark plugs both unnecessary and incompatible with how a diesel engine operates.

Combustion Process

First and foremost is the combustion process itself. As we’ve established, the extreme pressure of the compression stroke provides all the heat necessary for ignition. Introducing a spark plug would be redundant. The engine’s design is centered around creating this heat internally, making an external ignition source obsolete.

Fuel Properties

Diesel and gasoline are processed to react in contrasting manners when subjected to pressure.

Gasoline is extremely volatile which means it vaporizes and blends with air quickly. It is intended to be ignited by a spark in a way. If an air-gasoline mixture were compressed to the pressures, as diesel it would ignite too early and erratically causing what is called “knocking” or “detonation,” potentially damaging the engine. The spark plug plays a role in ensuring this ignition occurs at the correct moment.

Diesel fuel exhibits volatility and greater energy density. It possesses a flash point (the temperature where it releases vapors that can be set aflame) yet a lower auto-ignition temperature (the temperature at which it ignites on its own without a spark). This distinct mix renders it ideal, for compression ignition. It resists ignition but ignites dependably under the severe heat of compression. Trying to use a spark plug with diesel’s direct injection timing would be ineffective, as the fuel isn’t pre-mixed with air in the same way.

Off-Road Machinery Demands

This design directly enhances the durability and performance required by, off-road equipment. Removing the spark ignition system (spark plugs, ignition coils, distributor, high-tension wires) eliminates possible failure points. Diesel engines are constructed with parts—more durable pistons, connecting rods and cylinder walls—to withstand the high pressures of compression ignition. The robust construction is a factor explaining why diesel engines in heavy machinery can operate for thousands of hours under intense stress, with outstanding dependability and generate the enormous torque required to shift tons of soil.

Cold Weather Challenges for Diesel Engines

The concept, behind compression ignition is ingenious. It has a primary weakness: low temperatures. During conditions the engine block, cylinder head and piston made of metal serve as large heat absorbers. When the piston compresses the air, a substantial portion of the valuable heat is taken up by the cold metal parts.

This can prevent the air from reaching the required temperature for the fuel to ignite, leading to hard starting or failure to start altogether. This is the exact problem that glow plugs are designed to solve. By pre-heating the combustion chamber, they give the engine the thermal boost it needs to overcome the cold and achieve reliable ignition. For operators of heavy equipment in colder climates, functioning glow plugs are not a luxury—they are essential for starting the workday reliably.

Conclusion

In general, diesel engines do not have spark plugs because they ignite fuel by the high temperatures generated by high compression, rather than by spark ignition. This compression ignition method gives diesel engines obvious advantages in torque, durability and fuel efficiency.

Knowing this fundamental difference in ignition methods will help you better maintain heavy equipment and avoid confusing spark plugs with glow plugs. Diesel engines also have their own set of maintenance parts, and the parts that need attention include preheating plugs, injectors, etc. If these parts need to be replaced, FridayParts helps you reduce downtime, control costs, and get your equipment back to work as quickly as possible.

FAQs

What Are the Differences Between Spark Plugs and Glow Plugs?

The primary distinction lies in their roles. A spark plug serves as an igniter. It produces a high-voltage spark to initiate the burning of a -mixed air-fuel blend in a gasoline engine. A glow plug acts, as a heater. It does not generate a spark. Its sole purpose is to heat the combustion chamber in a diesel engine to facilitate ignition when starting cold.

In what way does a diesel engine initiate operation without the use of spark plugs?

A diesel engine ignites by utilizing compression heat. The piston compresses the air to such a degree that it heats up sufficiently to spontaneously ignite the diesel fuel. When the engine is cold glow plugs warm the combustion chamber beforehand to guarantee the air attains this ignition temperature.

How do diesel engines differ from gasoline engines?

The main differences are:

- Ignition Technique: Diesel motors operate with compression ignition whereas gasoline motors utilize spark ignition.

- Compression Ratio: Diesel engines possess greater compression ratios (17:1 or above) in contrast, to gasoline engines (approximately 10:1).

- Fuel Type: They utilize fuels (diesel, versus gasoline) that possess distinct characteristics.

- Power Output: Diesel engines generate higher torque (pulling force) at reduced RPMs making them perfect, for heavy-duty machinery.

- Efficiency: Diesel engines are generally more fuel-efficient due to their higher compression and the higher energy density of diesel fuel.