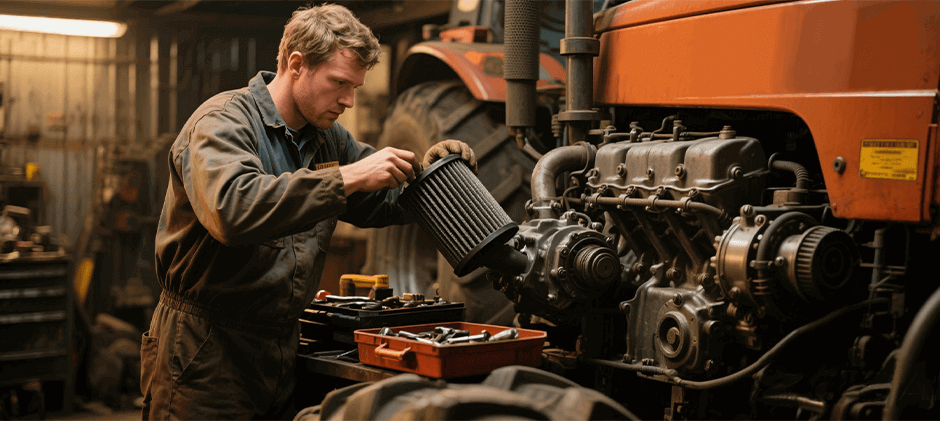

Cold starts, moisture, and dusty winter roads all put your engine’s breathing system to the test. When an air intake system struggles, fuel efficiency drops, filters clog faster, and internal wear accelerates. This article breaks down how to inspect and maintain your air cleaner assembly during winter so your off-road machinery runs reliably even when temperatures fall.

We’ll also look at practical ways to reduce maintenance costs—because in the U.S., where labor is expensive, knowing what you can do yourself and where to find quality parts economically can make a measurable difference.

Why Winter Maintenance on the Air Cleaner Matters?

When temperatures drop, moisture condenses inside the intake system and combines with dust. In heavy-duty off-road machinery—like loaders, excavators, and tractors—this build-up can form mud-like debris inside the air cleaner housing, blocking filters or freezing overnight.

Here’s what typically happens when winter air conditions meet a neglected cleaner:

| Symptom | Column 2 | Column 3 |

|---|---|---|

| Black smoke | Restricted airflow | Poor combustion efficiency |

| Loss of power | Frozen or clogged filter | Uneven air–fuel mixture |

| High fuel use | Dirty intake restriction | Compensating fuel injection |

| Hard start | Moisture in the air cleaner bowl | Inconsistent combustion |

Checking your air cleaner every few weeks in winter prevents these problems long before they drain productivity.

The Essential Air Cleaner Checklist

Regular inspections prevent small intake issues from escalating into repair bills. When working in freezing, dusty, or wet conditions, we recommend following this five-point visual and functional check:

1. Inspect the Filter Element

Remove the cover and check the filter element. Look for damp spots, ice crystals, or caked mud. Even a light frost blocks airflow more than you’d expect.

- Never tap a frozen filter—it damages fibers.

- Always let it thaw at room temperature before cleaning or replacing.

2. Examine the Air Cleaner Housing

Look for cracks, corrosion, or loose fittings. A damaged housing allows unfiltered air and dust into the combustion chamber. In winter, small cracks widen slightly under freezing conditions, so early detection matters.

3. Drain or Clean Pre-Cleaner Bowls

Some equipment, especially tractors or loaders, has pre-cleaner bowls. Clear condensed water or frost from these bowls regularly to avoid water carry-over into the intake.

4. Check Intake Hoses and Clamps

Cold temperatures harden rubber hoses, making them more fragile. Flex or twist them gently to ensure elasticity. Replace if you notice brittleness or small splits around the clamps.

5. Verify the Seal and Mounting Bolts

Winter vibrations and frequent maintenance can loosen fasteners. Reseal suspect joints to avoid bypass leaks. An air leak bypassing the filter can carry abrasive dust straight into the cylinder walls.

How Often Should You Replace the Air Filter in Winter?

Most heavy equipment manuals suggest replacing air filters every 500–1000 operating hours, but winter conditions cut that lifespan nearly in half. Short runs and cold starts increase moisture condensation.

As a rule of thumb:

Replacement cost is small compared to a cold-weather breakdown. And here’s a subtle budget insight: in the U.S., labor costs for on-site maintenance are high, so sourcing durable but reasonably priced aftermarket parts lets you save on service calls without cutting corners. For example, aftermarket air cleaner assemblies from FridayParts already include compatible filters and housings that meet OEM specifications for brands like Caterpillar, Bobcat, and Kubota—without dealership price tags.

Related Intake Components Worth Checking

Winter stress doesn’t stop at the filter. While inspecting your air cleaner, it’s smart to check the connected parts listed below. A weakness in any can affect the entire airflow chain.

| Component | Why It Matters | Winter Concern |

|---|---|---|

| MAF sensor | Measures the air volume entering the engine | Can freeze or gather condensation |

| Throttle body | Regulates airflow into cylinders | Build-up of soot or ice reduces airflow |

| Vacuum hoses | Maintain pressure balance | Cracking from temperature swings |

| Intake hose | Connects the air cleaner to the manifold | Hardens or collapses under cold load |

| PCV valve | Controls crankcase gases | May clog from winter sludge |

By cleaning or replacing these supporting parts early, you avoid compounding issues that mimic engine failure symptoms.

How to Identify Early Warning Signs?

Winter air cleaner issues often start subtly:

- Whistling sounds near the filter housing

- Uneven idle or slow throttle response

- A slight smell of unburned fuel at startup

- The restriction indicator is stuck in the red

If you notice any of these, it’s time to open the air cleaner lid and investigate. Cold air thickens oil residue inside the duct, trapping fine dust. Leaving it unaddressed can double the filter restriction within weeks. A quick inspection can prevent expensive diagnostics later.

Why Aftermarket Air Cleaners Are a Smart Winter Investment?

Many owners hesitate to use aftermarket assemblies, assuming OEM is always safer. But in most heavy-duty off-road cases, reputable aftermarket options from large distributors offer the same fit and often better parts availability.

At FridayParts, assemblies such as Air Cleaner 6700711 for Bobcat Loader S130–S205 or Air Cleaner Assembly 3A151-19100 for Kubota Tractor Series M8200–M9000 deliver dependable airflow protection at fair prices. Since the company holds inventory across four international warehouses, delivery times stay short—even during peak snow season.

This combination—OEM-level reliability plus cost-effective sourcing—helps offset high U.S. labor expenses. Put simply, if you can install a compatible cleaner yourself in less than an hour, you’re saving both downtime and labor markup.

Keeping a Maintenance Routine Through the Season

A proactive intake inspection schedule pays off. Use the plan below to keep your engine breathing all winter freely:

Weekly:

- Wipe moisture from pre-cleaner bowls

- Check filter indicators and hoses

Monthly:

- Remove and tap-clean outer filter (if dry-type)

- Verify seals and housing bolts

Every 2–3 months:

- Replace filter elements showing color change or moisture exposure

- Clean the throttle body and inspect sensors

This simple approach prevents minor condensation or dust intrusion from turning into mid-season mechanical failure.

Conclusion

Reliable winter performance starts with clean air. Maintaining your air cleaner and related components protects combustion efficiency, saves fuel, and extends engine life when conditions are toughest. The small midwinter effort you invest in inspection and timely replacement keeps your machines working instead of waiting for parts. For crews who prefer dependable, compatible parts without dealer prices, the high-quality aftermarket selections available at FridayParts Air Cleaner provide a practical, long-term way to keep heavy equipment operating smoothly—all winter and beyond.