From skid steer loaders to hydraulic excavators, the core components of every internal combustion engine may be considered as constituted by two parts: the camshaft and the crankshaft. Comprehending the distinction between these two shafts is not merely confined to the grasp of mechanical theory—it also facilitates the prevention of costly malfunctions, enhances the efficiency of torque, and ensures that your equipment can operate smoothly irrespective of terrain conditions or loading circumstances. In this guide, we shall elaborate in detail on the functions of the camshaft and crankshaft, identify signals serving as precursors to failure, explore the underlying causes of such malfunctions, and provide explanations on the procedures for replacing these components so as to maintain the continuous, smooth operation of your off-highway machinery.

Key Takeaway

The camshaft controls how your off-road engine breathes—opening and closing valves for air and fuel flow—while the crankshaft converts piston motion into the torque that drives your machinery. Both must work in perfect sync, and when one fails, the whole system suffers.

What Do the Crankshaft and Camshaft Do?

Before comparing them, let’s understand how they operate individually—and how they work together.

| Component | Main Function | Location in Engine |

|---|---|---|

| Camshaft | Opens & closes intake/exhaust valves | Cylinder head or block |

| Crankshaft | Converts piston motion to torque | Lower engine block |

Camshaft Function

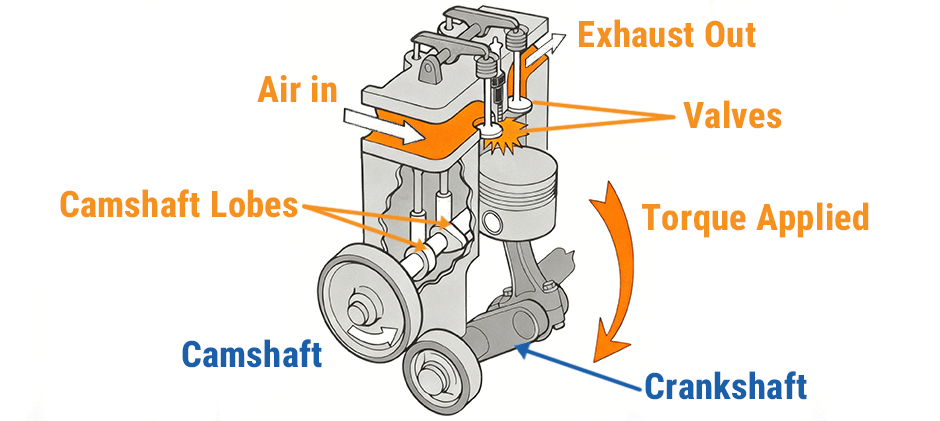

The camshaft is the precision-timing device of the engine. Its cam lobes push against valve lifters or rocker arms to open and close valves at the exact moments fuel and air need to enter—or exhaust gases need to exit.

There are typically two camshaft layouts in heavy equipment:

- Overhead Camshaft (OHC) – Located above the cylinder head for precise timing and higher efficiency.

- Cam-in-Block (Pushrod design) – Simpler structure, commonly used in tough off-road diesel engines where durability matters more than RPM efficiency.

Because the camshaft’s movement is linked directly to the crankshaft through a timing chain, gear set, or belt, it rotates once for every two crankshaft revolutions. This relationship keeps combustion timing perfectly synchronized.

Crankshaft Function

The crankshaft transforms reciprocating piston movement into rotational torque. Every piston stroke pushes a crank throw, converting explosive combustion into turning motion that powers the driveline, hydraulics, or output shafts in heavy machinery.

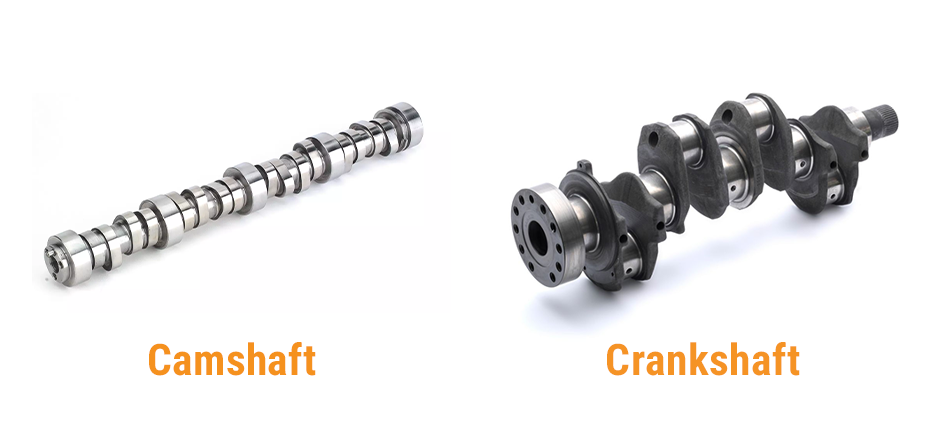

Typical crankshaft components include:

- Main and rod journals – bearing points for rotational motion

- Counterweights – balance the crankshaft during operation

- Flywheel flange – transmits torque to the driveshaft

- Oil channels – lubrication pathways

In heavy-duty engines, crankshafts are often forged from high-grade alloy steel for strength under constant pressure. If damaged, the torque output and engine stability drop drastically.

The Difference Between the Camshaft and the Crankshaft

1. Their Core Purpose

At the most basic level, the crankshaft converts the up-and-down motion of pistons into a rotational force (torque). That torque then travels through the drivetrain or hydraulic system, powering your bulldozer tracks, loader arms, or excavator hydraulics.

In contrast, the camshaft is the timing brain of your combustion system. Its rotating lobes push on valve lifters or rockers to open and close intake and exhaust valves with perfect synchronization. Without the camshaft’s rhythm, the crankshaft’s power goes to waste.

2. Location and Design

Inside most off-road diesel engines:

| Shaft | Location | Material | Key Components |

|---|---|---|---|

| Crankshaft | Deep inside the engine block (bottom end) | Forged or billet steel for extreme durability | Main journals, rod journals, counterweights, crankshaft pulley |

| Camshaft | Either in the block (pushrod design) or above it (overhead design) | Hardened steel or cast iron | Cam lobes, bearings, gear or chain drive, valve actuators |

The weight of the crankshaft is increased to a remarkable extent, as it must withstand explosive combustion pressures that may reach several thousand pounds per square inch (PSI) for each cylinder. Although the camshaft possesses a more slender structure, it is still required to maintain precision at the microsecond level, so as to guarantee that every valve-timing action remains accurate without deviation.

In contrast to light automotive engines, engines used in off-road vehicles generally adopt a gear-driven camshaft instead of a belt-driven one. Gears are capable of achieving a longer service life under conditions of vibration and temperature fluctuation, and they are also able to eliminate the possibility of slippage — a characteristic that is of essential importance for large diesel engines such as those employed in excavators and bulldozers.

3. Movement and Timing Relationship

During one full combustion cycle (four strokes):

- The crankshaft completes two rotations (720°).

- The camshaft completes one rotation (360°).

This 2:1 ratio ensures the valves open and close at the right moments relative to piston position.

If this relationship slips because of a worn timing gear or damaged tooth, the pistons and valves can collide—destroying both shafts instantly. That’s why periodic inspection of the timing components (chain, gear, or belt) is vital for maintenance planners in off-highway fleets.

4. Types of Systems in Heavy Equipment

- Gear-Drive Systems: Found on many large diesel engines like those in dozers and haulers. Gear sets directly couple the crankshaft to the camshaft for precise mechanical timing.

- Chain-Drive Systems: Common in mid-size loaders or compact excavators, balancing durability and maintenance cost.

- Belt-Drive Systems: Rare in heavy-duty engines due to exposure to debris and limited lifespan, though seen in lighter utility equipment.

Each system dictates the service life of both shafts and affects engine noise, efficiency, and ease of timing adjustments.

5. Materials and Durability

- Crankshaft Construction: Forged steel crankshafts resist bending and heat stress during continuous high-RPM operation. Vibration is dampened through a weighted crankshaft pulley to reduce harmonic resonance.

- Camshaft Construction: Generally made of chilled cast iron or tool steel. The surface of each lobe is hardened to resist friction from continuous valve contact. Camshafts also use camshaft components like bearings, followers, and lifters for smooth operation.

While both are built to endure heavy stress, their wear patterns differ—crankshaft journals typically experience oil film failure, while camshafts suffer from uneven valve lash or spring pressure wear.

6. How They Depend on Each Other

Neither the camshaft nor the crankshaft can function alone. The crankshaft provides the driving force, spinning via combustion power; the camshaft receives that motion through a timing transfer system.

If the crankshaft falters, the engine loses torque completely; if the camshaft fails, timing goes haywire, resulting in valve-piston contact or backfiring. Both must remain synchronized for complete engine “breathing.”

Here’s the dynamic in simple terms:

| Engine Stroke | Crankshaft Role | Camshaft Role |

|---|---|---|

| Intake | Pulls the piston down to draw in air and fuel | Opens intake valves |

| Compression | Drives the piston upward | Keeps both valves closed |

| Power | Rotates under combustion force | Holds both valves shut |

| Exhaust | Pushes exhaust gases out | Opens exhaust valves |

Proper valve timing equals correct air-fuel exchange, which equals maximum torque and fuel efficiency—two things off-road fleet owners cannot sacrifice.

7. Failure Impact Comparison

If any one of these components experiences a failure, the consequences may be considered extremely serious:

- Camshaft Failure: It may result in engine misfire, power reduction, or unstable idling. In modern engines equipped with variable valve timing systems, camshaft malfunction may additionally exert influence on fuel injection behavior.

- Crankshaft Failure: the outcome is even more severe—the seizure or cracking of bearings may cause the engine to become entirely unable to operate, and a complete reconstruction may be required.

For the purpose of ensuring mechanical reliability, it is essential to make use of high-quality replacement crankshafts or camshafts that have undergone off-road testing. Inferior or roughly processed parts may produce imbalance or journal taper, thereby causing premature wear to the entire lower section.

Bad Camshaft and Crankshaft Symptoms

Recognizing early warning signs helps you save on expensive overhauls.

Common Symptoms of a Bad Camshaft

- Tapping or ticking noise – caused by worn lobes or lifters

- Rough idling or misfires – valves aren’t opening properly

- Loss of power at acceleration – inefficient air-fuel mixing

- Metal shavings in oil – internal wear or broken lobes

Common Symptoms of a Bad Crankshaft

- Knocking sound under load – bearing wear or imbalance

- Oil leaks around seals – worn crank snout or seals

- Low oil pressure – worn bearings or damaged journals

- Complete engine lock-up – if the crank fails entirely

Often, technicians confuse camshaft wear with sensor malfunction, which is why both camshaft position sensors and crankshaft position sensors must be tested before assuming mechanical failure.

What Causes a Camshaft or Crankshaft to Fail?

Even premium off-road engines face extreme working conditions—heat, vibration, moisture, and heavy load cycles—all of which contribute to wear.

Top Causes of Camshaft Failure

- Poor lubrication – clogged oil passages or neglected maintenance.

- Improper valve timing – a loose timing chain or skipped gear tooth.

- Over-torquing bearings – uneven load on journals during reassembly.

- Contamination – dust or grit wears down lobes and followers.

To replace worn lobes or camshafts, it’s critical to use high-quality camshafts or camshaft components tested for heavy-duty applications.

Top Causes of Crankshaft Failure

- Low oil pressure – causes bearing scuffing and overheating.

- Overloading or detonation – produces torsional stress cracks.

- Misalignment – from worn engine mounts or bent connecting rods.

- Vibration neglect – causes harmonic resonance leading to fatigue.

When replacement is unavoidable, choose a crankshaft crafted from forged steel for durability under high compression. Don’t forget that the crankshaft pulley also plays a balancing role; a worn pulley accelerates crankshaft wear.

Maintaining Timing Harmony

In an off-road machine’s engine, the camshaft and crankshaft are connected through:

- A timing chain (more durable, preferred for off-road diesel engines)

- A timing belt (used in lighter units for noise reduction)

- Gear-driven systems (common in heavy machinery, where timing precision must be absolute)

Each mechanism must stay aligned. When valve timing drifts, cylinder compression drops, and the engine loses torque and efficiency. Always inspect tensioners, belts, or gears during every major service.

FAQs

Q1: Which part is more important, the camshaft or the crankshaft?

Both are essential—the crankshaft drives motion, the camshaft manages timing. Without synchronization, the engine fails.

Q2: Can a damaged crankshaft be repaired?

Yes, minor scoring can be ground and polished, but severe cracks require a new crankshaft.

Q3: What’s the role of the camshaft in off-road machinery?

It controls valve operation—ensuring torque and combustion efficiency are optimized for heavy terrain.

Q4: How do I know if my camshaft sensor is failing?

Watch for misfires, a drop in fuel efficiency, and the engine stalling intermittently.

Q5: When should I replace these components?

If you notice performance deterioration after 5,000+ operation hours or visible wear during engine rebuild inspections, replacement is advisable.

Conclusion

In any type of off-road machinery, the camshaft and the crankshaft may be regarded as existing in rhythm and power—neither can be absent. Only an engine that is balanced and possesses accurate timing is able to operate in a safe condition while delivering strong torque at the moment when it is most required. FridayParts provides aftermarket components of high quality, with pricing that remains affordable, durability that is sufficiently strong, and compatibility with a wide range of mainstream heavy-equipment models, thereby ensuring that your operations are able to continue in an efficient state. You may browse through our product catalog immediately so that your machinery may retain powerful output and maintain smooth operation.