In heavy‑duty off‑road equipment, reliability is everything. Whether it’s a loader, grader, or service truck running a 6.7 Cummins, a small part like the idler pulley can bring your whole operation to a halt.

That high‑pitched squeal from your engine bay? It could be a warning that your idler pulley bearing is going out. Left unchecked, it can damage your drive belt, disable hydraulics, and result in costly downtime.

This complete guide breaks down 6.7 Cummins idler pulley replacement from a fleet owner’s point of view — covering symptoms, cost, bearings, tensioners, and step‑by‑step repair tips designed for off‑road machinery.

What the Idler Pulley Does and Where to Find It

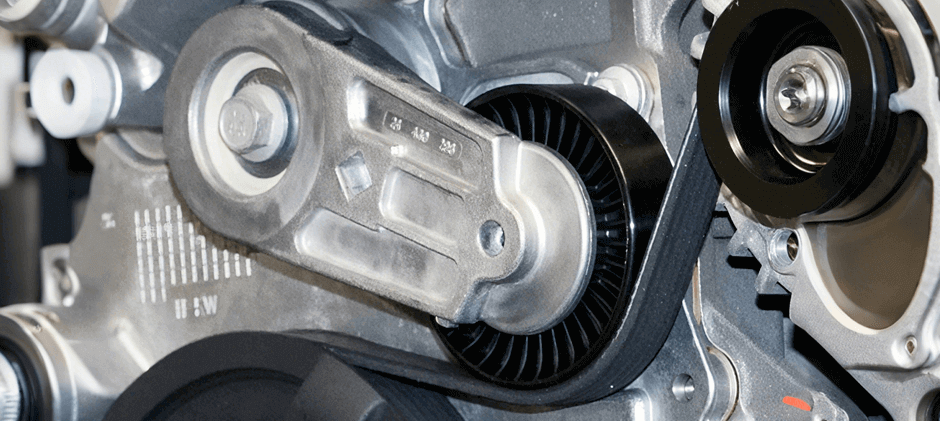

The idler pulley supports and redirects your serpentine (drive) belt as it travels around, rotating accessories such as the alternator, water pump, and hydraulic‑pump drive.

- Function: keeps the belt properly aligned and distributes load evenly.

- Location: on a 6.7 Cummins, the idler pulley is bolted to the front of the engine block, normally between the alternator and power‑steering or A/C compressor.

- Difference from a Tensioner Pulley: the idler pulley is fixed, while the tensioner pulley sits on a spring arm to maintain constant pressure on the belt.

This setup is similar to 5.9 Cummins, Dodge Ram 1500/2500, and even Duramax engines.

Symptoms of a Bad Idler Pulley

A worn or damaged pulley gives clear advance notice before failure — if you know what to look for:

- High‑Pitched Squeal or Grinding: a common sign of bearing failure as lubrication dries out.

- Visible Cracks or Surface Damage: indicates overheating or debris wear.

- Pulley Wobble: Try to wiggle the pulley back and forth. Any play or movement indicates the bearing is shot.

- Belt Misalignment or Fraying: result of pulley wobble or worn grooves.

- Accessory Drive Problems: weak hydraulic assist, charging issues, or cooling‑fan slowdown.

In demanding off‑road environments — dust, mud, and vibration — these symptoms accelerate quickly, especially if maintenance intervals slip.

6.7 Cummins Idler Pulley Replacement Cost

| Repair Option | Typical Cost | What’s Included | Best for |

|---|---|---|---|

| DIY Replacement Cost | $20 – $50 | Only the pulley; your labor. | Operators/mechanics with tools. |

| Professional Replacement Cost | $150 – $300 | Pulley + 1 hr labor. | Fleet shops or contractors. |

| Idler Pulley Bearing Replacement Cost | $10 – $25 | Replace bearing only; needs a press. | Advanced technicians. |

| Idler Tensioner Pulley Replacement Cost | $80 – $200 | Tensioner assembly + labor | Preventive maintenance combo. |

Just like the Ford F‑150 idler pulley replacement cost pattern, prices vary by region and labor rate.

Many operators choose to replace the idler, tensioner, and belt in a single downtime window — saving both time and future service calls.

When Should You Replace the Idler Pulley?

From the field and forums alike, mechanics agree:

- If the bearing spins freely without resistance, it’s dry — at risk of seizing soon.

- Once the tensioner shows wear, the idler pulley is usually not far behind.

- For easy‑access assemblies, replacement is cheap insurance against a broken belt that halts your shift.

So, while you might squeeze a few extra hours from the old pulley, it’s simply not worth risking a tow or lost production day.

Step‑by‑Step: Drive Belt Idler Pulley Replacement Guide

Replacing the pulley on a 6.7 Cummins engine used in off‑road machinery or trucks is straightforward with standard workshop tools.

Tools You’ll Need

- Ratchet & socket (13‑15 mm typical)

- Breaker bar or belt tool to release tension

- Torque wrench (≈ 37 ft‑lb / 50 N·m spec)

- Safety glasses + gloves

Procedure

- Shutdown and Disconnect: Park on level ground, cool the engine, and disconnect the negative battery cable.

- Relieve Tension: Insert a breaker bar into the tensioner’s square drive. Rotate to release tension, then slip the serpentine belt off one pulley.

- Remove Old Pulley: Loosen and remove the center bolt; slide off the bad pulley.

- Install New Pulley: Clean the mount surface, position the new pulley, tighten by hand, then torque to spec.

- Reinstall Belt: Follow the under‑hood or service manual routing. Ensure all grooves seat correctly before releasing the tensioner pressure.

- Final Check: Reconnect the battery, start the engine, and watch for straight belt tracking and noise‑free operation.

Pro Tip: Photograph the belt route before removal. Simple step, big time‑saver.

Related Components You Need to Inspect

- Tensioner Assembly: loses spring tension over time.

- Serpentine Belt: replace every 60‑80k miles or when cracking begins.

- Bearings & Seals: especially in dusty or sandy operations.

- Pulley Alignment: Check adjacent accessories for spacing or bent brackets.

Replacing these together ensures a balanced load, preventing premature failures under heavy off‑road vibration.

FAQs

Should I replace the tensioner and belt with the idler?

Yes. For off‑road fleets, downtime costs more than the parts. Replacing all three keeps your drive system reliable for the long haul.

Does this apply to 5.9 Cummins engines, too?

Absolutely. The 5.9 Cummins idler pulley replacement process is nearly identical — part numbers and torque specs might differ slightly.

Can I just replace the bearing?

Yes, but only if you have a press and precise alignment tools. For most field shops, replacing the full pulley is faster and safer.

How urgent is it to replace the idler pulley?

If noise or wobble appears, replace it immediately. A failed pulley can destroy your belt mid‑job.

How does this compare to a Duramax idler pulley replacement?

Nearly the same. The concept of belt routing and bearing wear applies to Duramax and Power Stroke engines as well. Use this guide as a reference.

Preventive Maintenance Tips

Experienced operators note: A $25 pulley can end a $10,000 workday if ignored.

The pulley’s bearing spins thousands of revolutions per minute under heavy load and extreme heat. Off‑road dust constantly threatens its seal integrity.

Grease breakdown leads to dry bearings that seize, shatter, and scatter debris — taking out the belt, fan, or radiator.

That’s why most equipment shops treat idler pulley replacement as scheduled preventive maintenance, not a random repair.

Conclusion

For off‑road machinery or diesel trucks using a 6.7 Cummins, replacing a noisy idler pulley is one of the lowest‑cost ways to prevent unplanned downtime.

Now you know how to identify failure symptoms, estimate the idler pulley replacement cost, and complete the drive belt idler pulley replacement yourself or at your local service shop. Find premium‑grade 6.7 Cummins idler pulleys, bearings, and belt‑tensioner assemblies at FridayParts — tough enough for construction, agriculture, and off‑road environments.